In the food ingredients and flavouring & spice manufacturing industries, balancing supply with demand and keeping operational costs to a minimum are key factors that can influence your position in the market place and improve your competitiveness.

In this blog, we look at how making some strategic changes to the production line, by decoupling key manufacturing stages, can help food manufacturers improve their productivity and achieve a competitive edge.

Is your production line flexible enough?

What do we mean by flexible? Can you make to order, produce both small & large volumes from the same line, manufacture during a whole shift? These are commonly the challenges that we help our customers to overcome. If your food production process isn’t flexible enough to meet the needs of today’s market place, with ever changing consumer tastes and new ingredients in recipes, you need to make a change. But what change will yield the best results?

Do you have a fixed, inline production system, whereby all the processing steps are linked together? Powders move from formulation to blending then on to packing, with each step having to wait until the previous one is completed? We see how these systems result in campaign manufacturing, excess inventory and warehouses full of finished goods storage.

There is an alternative to this, which lies in the creation of a container-based powder handling system. The achievement of this can be done in stages, with a change at each point yielding improved production results that can help to fund the implementation of the next stage. We call this decoupling.

How does decoupling production work?

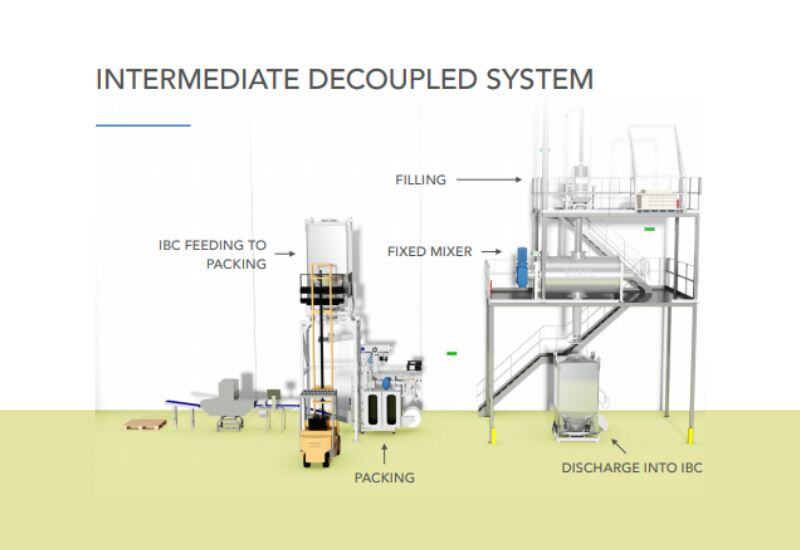

The first step to consider is decoupling your fixed industrial mixer. Maybe it is a ribbon blender or a plough shear mixer, which can mix a recipe batch in under 10 minutes. But have you considered the full Takt time and how long it takes to fill and empty, rendering the mixer idle until these steps are completed. What if you could decouple it from the production line? This could be one way to significantly increase your output as formulation and packing could run independently of the mixer.

The end point of decoupling is a full IBC system incorporating IBC blending at the heart of the operation. With the IBC becoming the blending vessel then the amount of time for cleaning between batch changeovers is significantly reduced. Advances in tumble blending and ancillary equipment, such as high shear and liquid addition, have expanded the range of recipes that container based mixing can cover.

Decoupling of equipment enables food manufacturers to perform each of the processes simultaneously which means that key machinery is running far more efficiently. The obvious benefit of this is up-time - by decoupling your fixed line process it can yield a range of additional benefits:

- Reduced cleaning time

- Reduced WIP and Inventory

- Quick response times for short orders

- Elimination of cross-contamination risks

- Lessons the amounts of wasted product

- GMP required hygiene levels

- Total control of any product at any station at any one time

- Factory space saving

If you compare this to a traditional fixed mixer system renowned for limiting production flexibility and long extended periods of time for clean-down cycles, it’s easy to see why decoupling is the choice of market-leading food producers.

In addition to production efficiencies, a fully decoupled system has another key benefit and that is better control over allergens. Cross-contamination of allergens poses a huge risk to consumers and is often a big problem for manufacturers of food flavourings and spices. Through decoupling using IBCs, manufacturers have the best of both worlds due to contained processing - the flexibility to handle short production runs and quick recipe changeovers without the risk of cross-contamination.

The Matcon system and how it solves food manufacturing challenges

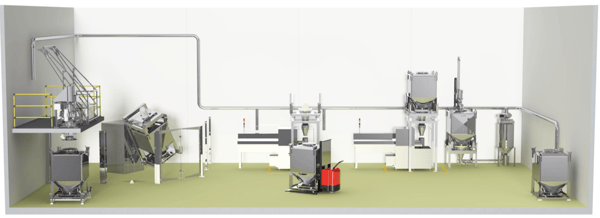

The factory layout below is an example of a system designed for a food ingredients manufacturer. Using Intermediate Bulk Containers (IBCs) throughout the production process means that all the process step run concurrently.

As one IBC is being processed on the blender, another is being formulated with the next recipe, another can be feeding into a packing machine, whilst a fourth IBC can be cleaned 'offline' and prepared ready to re-enter the production line as required. This enables all of the stations to be active simultaneously and optimised for high OEE rates. By incorporating container based manufacturing it is possible to increase the flexibility of the production line, reduce downtime and improve packaging line productivity.

The advantages of a decoupled system for Food Manufacturers:

In summary these are the advantages of using a Matcon container based manufacturing system:- Downtime decreased - the mixer can be loaded (charged) and in operation while your mixed product is being packed.

- Increased production - as the recipe is being directly formulated into an IBC you can setup for packing.

- No powder segregation - when using a Matcon IBC (which includes Cone Valve technology) materials will be discharged consistently, preventing segregation.

- Better containment – IBCs are sealed mobile containers that keep your powder ingredients inside.

The proof you need to gain confidence in making a change

Decoupling offers food manufacturers a huge opportunity to improve efficiencies, increase product ranges and ultimately outperform your competitors.

Leading food manufacturer, Rain Nutrience, approached us with a drive to realize these opportunities. Please find out how a decoupled IBC-led manufacturing process has supported their business growth ambitions.

Posted by

Matt Baumber