21 February 2025

In the food ingredients and flavouring & spice manufacturing industries,..

Eliminate waste and be able to rapidly respond to customer's needs with flexible and agile powder handling using Intermediate Bulk Containers (IBCs).

12 Min Read Time

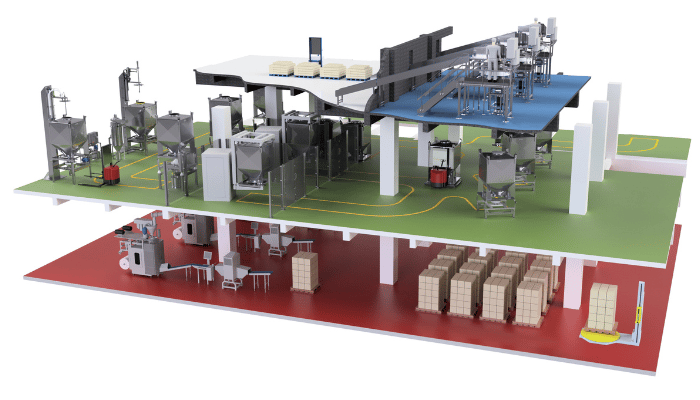

Parallel processing is the decoupling of each of the manufacturing steps so that formulation, blending, packing and cleaning take place simultaneously.

IBCs are used to transport material between the manufacturing processes, therefore each process step is independent of the other so no time is wasted waiting for the previous step to complete before moving on.

One recipe can be packed, at the same time as one is being mixed and another being formulated, whilst used IBCs are cleaned.

Typically Blending can be a bottleneck. With in-line systems such as pneumatic conveying or close coupled mixing towers, a hold-up in one area affects the whole process chain.

With IBC Systems there is no waiting at the blending stage. The Intermediate Bulk Containers (IBCs) are filled off-line and, as they also act as the blending vessel, they are loaded on and off the blender immediately.

As soon as one IBC is removed, the blender is ready to receive the next formulated container. No cleaning of the blender is required between batches or recipe changes.

This is in stark contrast to fixed mixer systems which can take a few hours to fill the mixer and then several hours to empty as they are coupled to the packing lines.

With an IBC Powder Handling System, there is no need to create WIP/WIQ to overcome bottleneck issues.

As the IBC is the blending vessel, it doesn’t need cleaning between recipe batches. Contrast this with an in-line mixing system, where the whole line has to be shut-down for hours.

We have created this Knowledge Hub of related articles to help you understand more about your powders and parallel processing.

Eliminate waste and be able to rapidly respond to customer's needs with flexible and agile powder handling using Intermediate Bulk Containers (IBCs).

With the Matcon Cone Valve technology you can overcome any powder handling issues including bridging, blocking and powder mix segregation.

Guidance, best practice articles and related reading for Parallel Processing.

Our team of experts are ready discuss how you can benefit from switching to parallel processing with a Matcon system. Contact us today.

At the heart of the Matcon system you will find the Cone Valve - invented, patented and developed by us. We help manufacturers overcome issues of mix segregation, containment and bridging that are inherent in traditional powder handling systems. Discover our unique approach to powder handling and the innovation that underpins all that we do.

About us