21 February 2025

In the food ingredients and flavouring & spice manufacturing industries,..

Ensure product quality with reliable powder feeds.

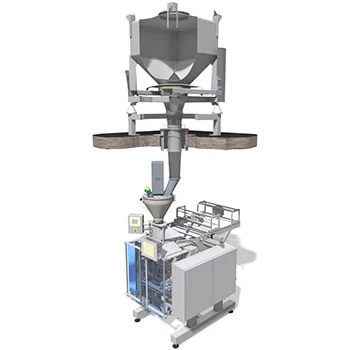

Discover a range of benefits with Matcon's powder recipe packing systems and machines.

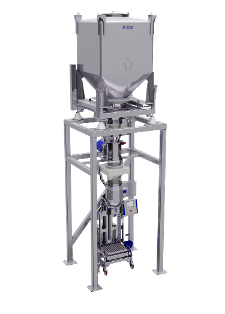

The automated, controlled flow of your powder recipes with complete discharge from original Cone Valve IBCs.

The unique Cone Valve technology within the Matcon IBCs prevents powder mix segregation, which is vital when accurately feeding to powder packing machines and third-party equipment.

Do you need further information about a Matcon Product? Complete the form and our team will contact you.

Discharge the IBC straight into FMCG packing systems without any secondary refill devices.

Automatic and controlled refill, producing a consistent feed, allowing packing lines to maximise their throughput.

Cone Valve technology protects against product segregation during discharge to ensure a quality product every time.

High manufacturing efficiency rates are possible as the IBCs provide a constant feed to the packing line hopper.

Fast changeover of IBC means the packing line can be kept running without significant downtime.

Assured product quality as product is transferred without the risk of segregation due to the Cone Valve technology within each IBC.

Consistent feed of product as the Cone Valve technology also protects against bridging and blocking.

Fully contained transfer of materials ensures that no product is spilt or leaks, thereby removing the risk of cross-contamination.

Keep the high-speed packing lines working efficiently with a consistent and controlled flow of material.

Our powder packing equipment is extensively used in the following industries:

Change recipes faster than ever with high accuracy, direct dosing from Matcon IBCs.

Fill into sacks/bags without the need for screw feeders.

Ideal for small campaign runs. Versatile enough to cover a wide range of powder characteristics from cohesive to free-flowing.

Full discharge & protection against segregation due to mass-flow.

Simple to use powder packing machine.

We specialise in providing complete materials handling solutions in the Food, Nutrition, Pharmaceutical, Beverages, Sports Nutrition, Nutraceuticals and Chemical sectors.

We’re not just an IBC provider, but a true partner helping you accomplish the right system for your needs.

Using Intermediate Bulk Containers (IBCs) to transport powders between manufacturing steps and to blend powders to a homogenous mix.

Matcon IBCs are efficient, dust-tight powder containers, manufactured to the highest standards for all industry applications.

Formulate powder recipes directly to IBCs with accurate, automated filling and add into your batch processing flow as required.

Mix powder recipes of all sizes any time using an IBC Tumble Blender. Improve loading times, cleaning and remove bottlenecks.

Over the years we have seen a wide range of different powder types and production issues that our Cone Valve technology has been able to overcome. This gives us the confidence to believe we can handle any challenge you wish to put to us.

© Copyright IDEX 2024

Privacy Policy*Required Fields