The cleaning of equipment and production facilities is an essential task for any food manufacturer, but it can consume valuable production time. Imagine if this could be reduced or even removed from your production process without affecting hygiene or product quality.

What if you could reduce the need to clean between recipe changeovers or batches and simultaneously enhance your production line capacity? How much could your throughput be increased?

In this blog we’ll look at the cleaning methods currently deployed in some manufacturing processes that handle food powder solids, the shortcuts some manufacturers take to offset lost production time and how to improve productivity. We’ll also explore an alternative production methodology that could significantly improve your efficiency and ability to deliver a portfolio of products.

The problem with in-line processing

Consider your current production processes; your last recipe run is fulfilled, the product has cleared the line, it is packaged and ready to go. Now it's time to clean down all those tricky pipes and fixed pieces of machinery before you can process your next recipe.

A major setback with the in-line production process is that manufacturing has to stop completely while you wait until the machinery has been taken apart, cleaned and then reassembled. This can take a significant amount of time, especially when you include the waiting time for equipment to dry (following a wet wash) and for swab test results to validate cleaning.

We have seen manufacturers of food and flavourings spending excessive amounts of their production time cleaning equipment - laying on extra shifts to fulfill cleaning needs. This represents a significant amount of production downtime and lost manufacturing capacity. Furthermore, equipment standing redundant results in a low Overall Equipment Effectiveness (OEE) score. In comparison to other manufacturing facilities with leaner production processing in place, facilities using in-line processing suffer greatly from reduced productivity.

Cleaning shortcuts are not good practice

Some businesses take cleaning shortcuts. Here are some common, risky cleaning substitutions that we would recommend to be avoided:

Risky Cleaning Alternative #1 - White to Black Production

Some food manufacturers attempt to avoid cleaning after every recipe change by using ‘white to black’ production methods. For instance, a food manufacturer might begin the day with a bland based recipe, moving through to the stronger colour/flavoured recipes as the day progresses. Since each succeeding recipe has a more intense colour/taste than the previous one there’s no noticeable transfer of colour/flavour between each batch.

The major shortcoming with white to black production is that the product will not exactly match the ingredients listed on the label. To follow Food Standards legislation, whatever is in the product should be included on the label. Food manufacturers who don’t adhere to food standards legislation could face large fines and reputational damage.

Risky Cleaning Alternative #2 – Flushing

Another way some food processing systems try to reduce cleaning time is to flush the production system with a cheap base material to remove the last product from the system.

Whatever material you use to perform a flush-through, no matter how inexpensive, it is still waste and the costs can quickly add up. Also, you still have the same problem as with the white to black methods; that your product will not exactly match the ingredients listed on the label.

A word of caution - please note that when using allergenic ingredients, none of the above shortcuts can be used, there is too high a risk to your customers and your business reputation. Products containing allergenic ingredients require a full clean down after every recipe changeover with cleaning validation and auditing to ensure no risk of cross-contamination.

The challenges with fixed Industrial Mixers

Large fixed mixers, such as ribbon blenders or plough shear mixers might blend ingredients quickly, but they take a considerable amount of time to wash and ensure they are fully hygienic. Clean times can escalate as you reach into every section and crevice to ensure your production line is clinically clean. With many ribbon blenders there are also zones when the blades do not make contact, leaving powder in the vessel. As a large fixed mixer is taken out of circulation to be washed and dried, machinery sits idle and operators have to wait before the next recipe batch can commence. In addition to the time lost, cleaning your equipment involves considerable costs in terms of water usage, cleaning products, energy and manpower which greatly affect profitability.

See how to turn cleaning time into production time in 3 simple steps...

- Initially you need to know how long you currently spend on cleaning. Add your figures into our ROI calculator to find out how much time you lose over the course of a year and what this represents in cost and lost capacity.

- Regain that cleaning time and utilise that time to make more product by switching to a more flexible, efficient manufacturing system.

- Re-enter your new results into the ROI calculator after using the flexible manufacturing system to calculate your increased revenue, amplified production levels and time saved.

Introducing flexible, efficient food manufacturing with minimal cleaning downtime

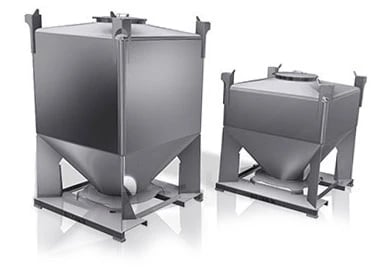

Today’s food manufacturers know that operating lean is the way to generate more profit. Intermediate Bulk Container (IBC) manufacturing systems provide a cost-effective way to add flexibility to your production line.

With IBC manufacturing, mixing is completed in-bin, the mixer doesn’t come into contact with the product, so cleaning time is significantly reduced. This sealed, mobile system enables different products to be mixed one after the other on the tumble blender, with only a short break to switch an IBC containing blended ingredients, for one containing unblended ingredients – what you could term SMED. The used IBC, once emptied, is taken to be cleaned off-line while a new IBC is attached to the mixer, facilitating continuous production.

If your products are sticky or contain allergens and have longer cleaning times or require enhanced validation to certify full hygienic cleaning, you can still continue to manufacture. All production processes continue to operate throughout the shift without any downtime while cleaning takes place offline. You may just need a few more IBCs that can wait off-line in cleaning quarantine, whilst the production line keeps moving.

Discover how a shift to IBC based manufacturing could yield significant returns in production efficiency and reduced downtime. Download our ROI calculator and take your first move to improved productivity.

Posted by

Matt Baumber