Maintaining the happiness of your operators and creating a positive working environment is hugely important to manufacturing leaders. Yet despite this, manufacturing managers increasingly find themselves failing their staff, through circumstance rather than intention.

Food nutrition and nutraceutical businesses are experiencing huge shifts in manufacturing batch sizes and recipe combinations, all fueled by the consumers insatiable appetite for variety. At the core sits manufacturing operations who are expected to deliver these requirements, often with processes and equipment that was installed years ago, when consumer demand for variety was a fraction of what it is today. Inevitably this results in inefficient production processes, increased cleaning / downtime, higher occurrences of cross-contamination, poor allergen control and ultimately demoralised operators. So, what can you do to meet market demands, whilst keeping your manufacturing house in check?

We sat down with Phil Spuler, a Manufacturing Process Engineer at Matcon to find out what he would recommend to manufacturers experiencing these issues.

Helping your operators ultimately helps you

When we talk to manufacturers engaged with food nutrition & nutraceutical production, their first concern is how can they address these problems within a limited budget? Clearly a new facility is the fastest way to seamlessly fix it, but if budgets are limited that doesn’t mean that existing manufacturing lines can’t be enhanced and optimised to meet the demands of today’s consumers.

There are a number of things you can do, but the simplest and most cost effective is the addition of IBCs (Intermediate Bulk Containers) to your processing line. These mobile, sealed vessels can be used to formulate, blend and pack-off your ingredients. But the crucial point is that they enable you to undertake all production processes at once across multiple batches - what we call parallel processing. There’s no idle equipment waiting for a previous process to complete and no onerous cleaning requirements. These are simple modules that can fit into your existing production line and scale as you grow.

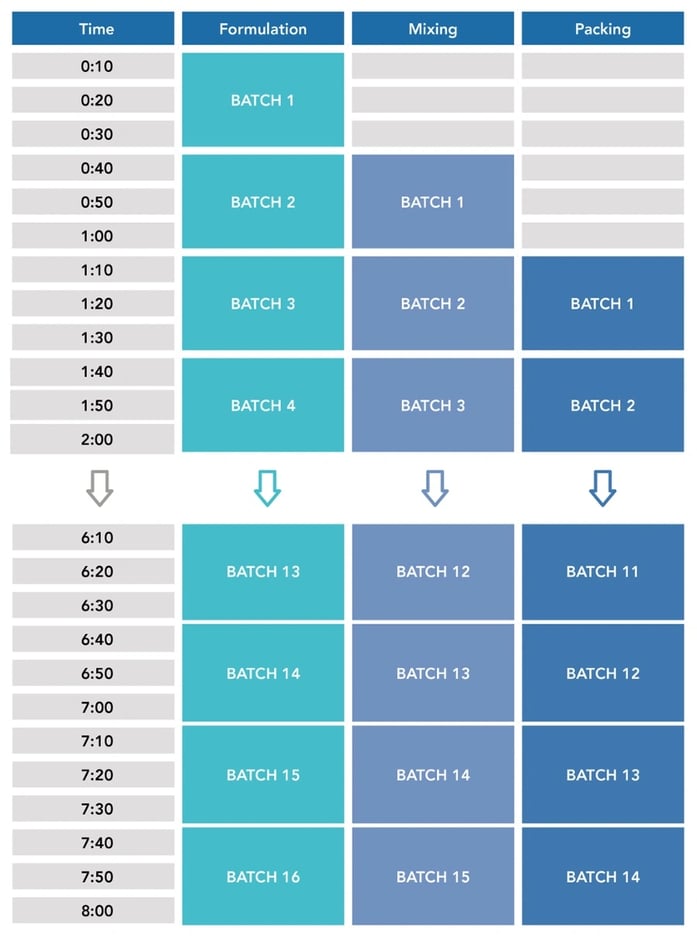

Here is an example of production capacity improvements that can be realised when parallel processing is deployed using a flexible IBC system. By the time the first IBC gets to the packing step, there is a second IBC at mixing and a third being formulated. Ongoing each processing step takes place concurrently so more batches can flow through the line during the shift. If the steps had to take place consecutively, one after the other then a third of the batches could be made:

How Can Smaller IBCs Produce More Product in a Day When a Fixed Mixer Holds 6000L?

A customer once queried why his company should consider using a 3500L IBC when their current fixed mixer held nearly double that amount at 6000L?

In answer, we proposed that in an 8hr shift, with an IBC system, double the amount of product could be generated. This is because the IBC system is continually processing in all stages of manufacturing. Formulation and cleaning are done offline and there is no bottleneck at blending as all the product is contained within the IBC itself so there is no need to clean between batches and no down-time.

On the other hand, the large scale fixed mixer has to be taken offline while filling and formulation take place, which can take a considerable amount of time given the 6000L capacity being filled from 25kg sacks. Then, once mixing is completed, the mixer has to be emptied into packing, followed by cleaning. Again, this can take many hours to complete. Because the processing of powders in a fixed mixer system is linear it means that only one batch can be fulfilled at a time, each process step has to wait for the one before. This results in considerable amounts of down-time at each process step.

In some industries, if there are variations in the recipes e.g. alternating colours or flavours, even less quantities can be produced in a day with a large fixed mixer, reducing production significantly due to the need to clean between every batch/recipe. However, with an IBC system, the IBC itself becomes the blending vessel, meaning that there is no down-time for blender cleaning between batches. Simply switch out the IBC and you are ready to go - what is called SMED (single-minute exchange of die) in lean manufacturing terms.

Why Not Generate as Much Stock as Possible in a Day?

Another facility manager once asked why they should produce less than the 6000L of powder that the mixer could hold?

It was found that their client had only ordered 3000L, but they made the full 6000L that the mixer could carry and stored the other 3000L excess as Inventory. However, what they failed to notice was not only were they using up valuable factory space, but that the product could expire before it got sold. In this case, if they had been able to produce smaller batches matched to the order size, it would free up capital which could then be invested back into the company.

This flexibility of batch sizes is possible with an IBC system as different sized IBCs can be used on a single mixer plinth and the volume fill rates can also be adjusted to suit order sizes. No more need for inventory and tying up valuable capital. With the range of products that a nutraceutical company will sell, this has to be the way forwards.

Try Out Our ROI Calculator for Better Mixer Utilisation

Use our processing calculator to input your own actual time and volume figures. This will help you discover the specific savings that your facility could make by implementing an IBC system.

Here Phil summarises the benefits of moving to an IBC based production system which serves as a great crib sheet if you’re considering making a change to your own processes.

Multi-functional - mobile solutions for numerous processing applications designed in 316L/304L stainless steel with hygiene and safety in mind (no hollow sections or enclosed crevices to trap product / contaminants).

Cleaning offline - a Matcon IBC allows for offline cleaning while other steps of your process are completed, decreasing the down-time of your system.

Contamination free - due to the IBC being the blending vessel, it means that no product comes into contact with the blender, so operators can switch between recipe without needing to clean down the blender and without risking cross-contamination. In addition, because the IBCs are sealed units (dust-tight) it removes the chance of product transference and decreases the risk of allergen contamination.

Save time – with some traditional, fixed mixer systems, processing can take as long as 8 hours with all the time it takes to fill, empty and clean the fixed mixer. However, with IBCs, you can create an agile system that can match batch sizes exactly and create a continuous flow of a range of products.

Perfect powder flow - IBCs can manage and contain the discharge of any type of powder with Matcon’s unsurpassed Cone Valve technology, reducing usual material flow challenges such as segregation, rat holing, bridging, blocking etc.

Space saving – in contrast to most fixed mixers, which take up plenty of workplace space, an IBC blender is exceptionally compact.

Increased production - an IBC blender can perform the function of several standard fixed mixers, enabling 3 or 4 batches of product processing per hour.

Flexible - one IBC blender can adapt to accept several sizes of Matcon Intermediate Bulk Containers or IBCs can be filled partway in order to create different batch sizes from one blender.

Cost saving - for companies using this modular system, the cost and time savings are enormous through the saved facility space and increased production efficiencies.

Don’t Just Save Your Operators’ Time When Manufacturing Your Food and Nutraceuticals

Although your operators will thank you for making their working lives less stressful and more efficient, that’s not all that introducing IBCs to your facility will improve. The cost, time, space, contamination, allergen and waste savings are substantial for manufacturers in today’s competitive market.

Read one of our customer’s stories to hear how Matcon have helped other manufacturers, or if you would like to speak with Phil, please contact him via our Contact Form.

Posted by

Phil Spuler