The packaging industry has evolved significantly, shifting from its core raison d'être of protecting products to enhancing brand identity, adopting eco-friendly practices, and crafting engaging unboxing experiences. Amid these changes, the quality of your product remains paramount. Customers should expect a great experience every time.

At Matcon, we take powder handling seriously. We recognise these evolving challenges and offer solutions tailored to the needs of modern manufacturing environments and changing consumer tastes.

Why Matcon's IBC Systems

Matcon's Intermediate Bulk Container (IBC) based system solutions can be configured to provide exceptional packing efficiency. The system design will consider batch sizes and pack-off rates, with IBC sizes and blending being matched to achieve efficient powder supply to the packing stage. Our technology is adaptable to variations in order sizes. It supports expanding product portfolios, offering a versatile and scalable solution that helps manufacturers meet customer-driven product variety, stay ahead of industry trends, and customise production based on demand.

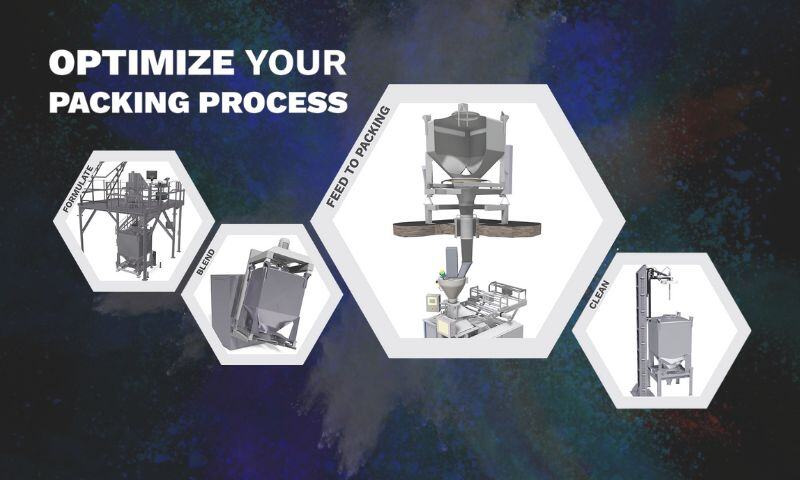

Optimise the Packing Process

At the packing machine interface, a Matcon IBC combined with the Discharge Station ensures a smooth and consistent material flow directly to the packing line hopper, thanks to the Matcon Cone valve's positive shut-off. This allows for a constant powder flow, even for sticky, cohesive powders, with essentially no dead volume.

This eliminates the need for secondary feeders and ensures a constant supply of powder, which enables the packing equipment to operate effectively and efficiently. Furthermore, the Cone Valve technology in each IBC prevents product segregation and degradation, ensuring the final product is of the highest quality.

Key Advantages:

- Consistent Material Flow: Our IBC systems ensure a steady supply of materials to the packing line, minimising the risk of production interruptions.

- Protection Against Segregation: The Matcon proprietary Cone Valve within each IBC ensures that products are discharged without segregation, maintaining product integrity.

- Fast Changeover: The quick changeover capability of IBCs means minimal downtime, allowing the packing line to keep running efficiently.

- Containment: Fully contained transfer of materials prevents dust release, removing the risk of cross-contamination and reducing cleaning time.

Real-World Application

A prime example of our system's effectiveness is BOH Plantations, Malaysia's leading tea producer. BOH transitioned from hand-feeding low-speed packing lines to using high-speed lines. This upgrade was possible because the Matcon IBCs could supply the higher volume demanded by the packing equipment and support multiple packing lines from a single Matcon blender. The result was a significant improvement in production capacity and product quality.

Customer Testimonials

It's not just Boh Tea; here is what other customers say about us:

-

Alimenta AS, Norway: "We started with blending and packing using Matcon's powder processing system in 2010. Since then, we have produced thousands of tons every year. We are very satisfied with the durability, efficiency, accuracy, and flexibility that the Matcon system provides." – Morten Anderson, General Manager

-

Arne B. Corneliussen AS, Oslo, Norway: "Our investment in Matcon’s equipment and expertise has provided a 100% improvement in efficiency due to running our mixer and packing lines in parallel. Cleaning and changeover times have dramatically reduced, providing quicker throughput and increased packing capability." – Mr Henry Bakkejord, Operations Manager

Trends and Challenges in Powder Processing & Packaging

The powder processing and packaging industry continuously evolves, presenting new challenges and opportunities. Key trends include:

- Increased Demand for Flexibility: Manufacturers need systems that can handle a diverse range of products without extensive downtime for cleaning and changeovers.

- Regulatory Compliance: Meeting stringent regulatory standards like FDA, GMP, ATEX, and EHEDG is critical for ensuring product safety and market access.

- Sustainability: There's a growing focus on eco-friendly practices, including reducing waste and energy consumption in manufacturing processes.

Matcon's solutions address these trends by providing flexible, compliant, and efficient systems that enhance productivity and sustainability.

Conclusion

Predictable powder flow is vital for efficient and high-quality powder processing and packaging production. Matcon's IBC systems offer a reliable, scalable solution that addresses common challenges and supports long-term operational success. Whether upgrading an existing facility or designing a new one, our expertise and technology can help you achieve your production goals.

Contact us to learn more about how Matcon can transform your powder handling operations. Let's work together to enhance your manufacturing efficiency and product quality.

Posted by

Matt BaumberTopics:

Powder Handling