Whether you are a start-up sports nutrition manufacturer or an established player, you will always be looking to operate your business efficiently and with integrity. We appreciate that it can be difficult to know which equipment to choose to ensure you meet your objectives, so to help you identify the best equipment and factory design, we have highlighted the strengths and weaknesses of three commonly used systems.

You can download our guide to provide you with an overview of the three systems and to help you understand how each may impact your production activity. In this blog we discuss the first factory scenario examining a conventional system that uses a fixed mixer.

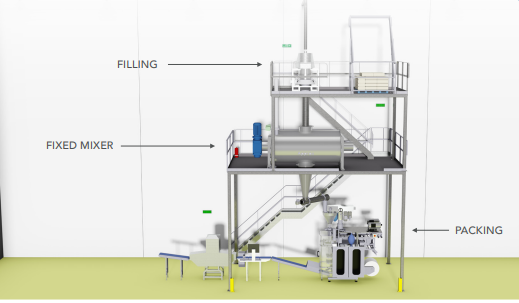

A fixed mixer conventional system is often used by start-ups as the machinery costs can be cheap (in the short term) and help you get your production up and running with lower ‘up front’ costs. This setup is also seen regularly in single product processing (although rare in the sports manufacturing industry).

Most sports nutrition manufacturers will initially get started with small fixed lines to produce a limited number of products and whilst this does provide benefits for a start-up, it can restrain and limit production flexibility as the business grows.

Sports Nutrition Manufacturers Need to Look at the Bigger Picture

A fixed mixer conventional system might be cheaper to setup and run but it is important to consider the longer term hidden costs such as the restrictions it may place on production and the downtime that could occur when regularly servicing older equipment.

Rather than let the machinery cost determine your factory design manufacturers should consider:

- The size of the batches that will be produced?

- How often the recipe will be changed?

- If there is a risk of cross-contamination as you change to a new recipe?

- If the product or recipe contains any potential allergens?

The sports nutrition industry is an extremely competitive one.

Manufacturers need to meet consumer demand, which often means producing a range of products to cover a variety of flavours and diet preferences. The number of products manufactured to serve consumers with intolerances, such as lactose and gluten, is also increasing and therefore anyone in this industry must have equipment to enable them to be flexible enough to produce a range of recipes and batch sizes without increasing the risk of contamination.

See How a Matcon Blender Compares?

What do Sports Nutrition Manufacturers need from their Production System?

To meet with the changing buying preferences of consumers, Sports Nutrition Manufacturers will often need to produce a range of flavours in small batches. This means that ingredients and equipment will need to be changed over regularly. The machinery will need to be regularly cleaned with air or if potential allergens are used, a wet wash will be required. The machinery will then need to be setup 'as new' to ensure there is a ‘clean’ production line, avoiding any cross-contamination of your product.

To meet this requirement, a processing system that enables quick batch changeovers and material handling in tightly controlled, enclosed containment units is essential. This not only ensures that you can meet consumer demand but also maintain product integrity.

In a competitive market place, sports nutrition manufacturers with limited resources cannot afford to waste time cleaning when they could be manufacturing to order and meeting demand.

Outputs and Hold Ups

With a fixed production line, output can be limited as the capacity of the mixer determines the amount of product that can be manufactured in a single run. The mixer must be filled and discharged a few times per day with a single recipe to make production worthwhile. This setup works well, until you need to perform a full clean down, which will often also include clearing up any dust from this non-contained process.

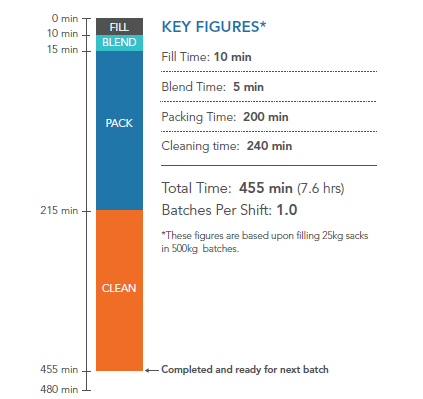

Typical production values (as shown in the resource below) for a fixed line, suggest that you could spend a complete shift (8 hrs) producing 1 batch. If you need to changeover this could result in spending almost one entire day cleaning down the machinery. If you needed to change recipes you would have to clean down after each batch, adding at least 4 hrs of cleaning each time. This would ultimately mean losing a half/whole day of production time.

Why Limit Yourself to a Fixed Production Line

Even if you are starting out as a small business, producing one batch at a time just doesn’t yield enough profit margin, especially when regular cleaning is required. Likewise, only producing one recipe variable is not a sensible business plan in today’s competitive sports nutrition market.

If you had the ability to produce multiple batches consecutively, imagine how much productivity could increase. Look at the metrics in our FREE guide to learn more and discover how you can future proof your manufacturing process from the start…

Posted by

Matt Baumber