Going from garage start-up to larger scale production can be a daunting prospect for manufacturers in any sector, not least in the high competition, high stakes sports nutrition industry. It all seemed so simple when you were filling, blending and packaging products by hand, but manual materials handling just isn’t going to cut it if you’re serious about expanding your sports nutrition manufacturing empire. So what are the options?

Continuous production and fixed mixers

Continuous production lines are what most people think of when they think of a sports nutrition manufacturing facility – conveyor belts, pipelines and machines all coupled together to take materials on a non-stop journey from raw ingredients to finished, packaged product.

However, there are a number of drawbacks to a continuous system that can impact your overall productivity and efficiency. Here we look at the benefits and disadvantages of the fixed mixer system, and propose a leaner, cleaner, alternative way of blending your recipes.

How does a fixed mixer work?

Fixed mixers are essentially large receptacles into which you pour your raw powdered ingredients. Regardless of whether that product is a protein shake mix, a nutritional supplement or the dry ingredients for an energy bar, the ingredients for a given product all get blended together to make your recipe – which can then go forward for further processing or packaging.

Fixed blenders usually work very quickly and efficiently, with a rotating blade that folds and mixes the various ingredients together to produce a consistent, even mix.

Drawbacks of a fixed mixer system

Sports nutrition manufacturers often underestimate the time it takes for their operators to fill and empty the mixer. This miscalculation is because some industrial mixer providers use a “4 minute blend time” in their advertising or sales pitch, but what they fail to include is the fill/empty time which could take up to 2 hours to fill and a further 2 hours to empty. In addition to this, cleaning time is usually overlooked. Importantly, the mixer is often left idle while filling, awaiting packing call off and cleaning activity takes place. Quite quickly you can see how much more sports nutrition manufacturers could produce, if the mixer was working more efficiently and how much time is wasted with traditional mixers.

Another important limitation of the fixed mixer system is that, being fixed in place, you only have one blender per production line to do the job. So, if you needed to increase the batch volume of a particularly best-selling product, you’d be restricted by the size of your blender. Likewise, if you wanted to reduce the batch volume, your large, fixed blender would be working at suboptimal efficiency.

What’s the alternative? IBCs!

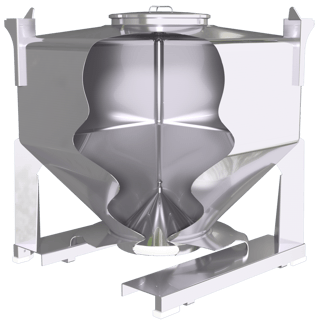

A leaner, cleaner alternative to using a fixed mixer is to use an Intermediate Bulk Container (IBC) system instead. These containers are not only transport receptacles to move powdered ingredients around your factory floor, but Matcon’s IBCs also double as the blender vessel.

Matcon IBCs are not fixed to a continuous system – you can swap these affordable, different sized containers in and out of a production line, allowing you to easily change your recipe and/or batch volumes to suit your production needs. As they decouple the manufacturing system it allows each part of the process to operate at its optimal capacity. The blender OEE rates can be much improved.

Unlike other IBCs that still use the butterfly valve discharge system, Matcon has developed a precision-engineered Cone Valve discharge system. This dust-tight technology allows precisely measured quantities of blended recipe to be discharged from the IBC, without any loss of product caused by escaping dust, left-behind residue, or sticky powders causing blockages. It also means that product is transferred without the risk of the recipe de-mixing. For more information on sports nutrition manufacturing, read our other blogs in this series.

Why not give one of our engineers a call to discuss how you could use a Matcon IBC system in your sports nutrition manufacturing facility?

Topics:

Sports Nutrition