In the paced realm of battery production, there is pressure to drive innovation, expand operations, and uphold strict quality standards. Amidst this flurry of activity, the crucial role of powder handling often goes unnoticed. However, this underestimated aspect can have an impact on efficiency, product quality and overall sustainability

The Dilemma in Battery Production

Battery makers encounter a set of challenges. They must navigate between production needs and term strategic objectives while upholding high quality standards, managing costs effectively and promoting environmental responsibility. Achieving this balance demands an approach that addresses both present requirements and future growth potential.

The Significance of Powder Management

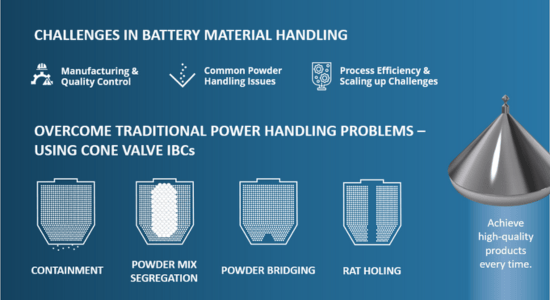

Although powder handling may not always be in the spotlight when discussing battery advancements, its significance should not be underestimated. The quality and homogeneity of battery powders play a role in determining the performance and dependability of the end product. Powder handling problems such as maintaining powder purity, preventing moisture ingress, and ensuring homogeneity across batches are critical considerations that can make or break production efficiency.

Expansion Phase: A Crucial Turning Point

As battery manufacturers transition from small-scale operations to large-scale production, the complexities of powder handling increase exponentially. While effective for proof of concept, traditional methods involving Flexible Intermediate Bulk Containers (FIBCs) and sacks often present inefficiencies at scale. These can include increased manual handling, frequent changeovers, and heightened risk of contamination.

The need for a more advanced modular approach is pressing as production volumes grow. Scalable solutions that can adapt to the intricacies of evolving battery powders and growing production demands are essential for long-term success.

.webp?width=550&height=300&name=Pipe-big-bag-IBC%20(1).webp)

Strategic Powder Handling: A Key Element in Achieving Success

Implementing advanced IBC system-based powder handling solutions can address many of the challenges faced by battery manufacturers:

- Quality Assurance: IBC systems can maintain consistency and purity across large batches, which is crucial for producing high-performance batteries.

- Efficiency Improvements: A decoupled powder handling can reduce production times, minimise waste, and optimise resource utilisation (OEE).

- Scalability: Modular systems that allow for seamless expansion as production needs grow, providing a future-proof solution for evolving businesses.

- Sustainability: Efficient powder handling and process could contribute to waste reduction and energy conservation, aligning with broader sustainability goals.

.webp?width=550&height=300&name=Hot-powder-IBCs%20(1).webp)

Moving Forward

To enhance their operations battery manufacturers can benefit from collaborating with experts, in powder handling. Such partnerships offer insights and solutions that can optimise production processes, reduce powder wastage, and establish sustainable manufacturing practices.

In the changing landscape of the battery industry, those who understand the significance of powder handling are better equipped to tackle future challenges. By embracing powder handling techniques, manufacturers can lay a strong foundation for sustained success by balancing immediate production requirements with long-term scalability and innovation.

For details, on our range of powder handling systems tailored for battery manufacturing applications please refer to our brochure.

Posted by

Matt Baumber