Reliable Feeding to Tablet Press

The Matcon Cone Valve within the outlet of each IBC enables product to be rapidly & automatically fed into the tablet press without risk of segregation which protects the content uniformity (CU).

The Cone Valve creates mass-flow discharge which means that all particles move down through the IBC together keeping the blend uniformity throughout the discharge process. This maintains the content uniformity (CU) which is not always the case with traditional butterfly valve bins.

Handle Difficult Powders

The Matcon IBCs are designed to safeguard against powder rat-holing, bridging & blend compaction. Also preventing material retention and material sticking to walls, which would affect the consistency of feed to the tablet press.

The Cone Valve promotes controlled flow even when handling notoriously difficult products such as metformin. Take a look at our case studies for proof.

Features at a glance

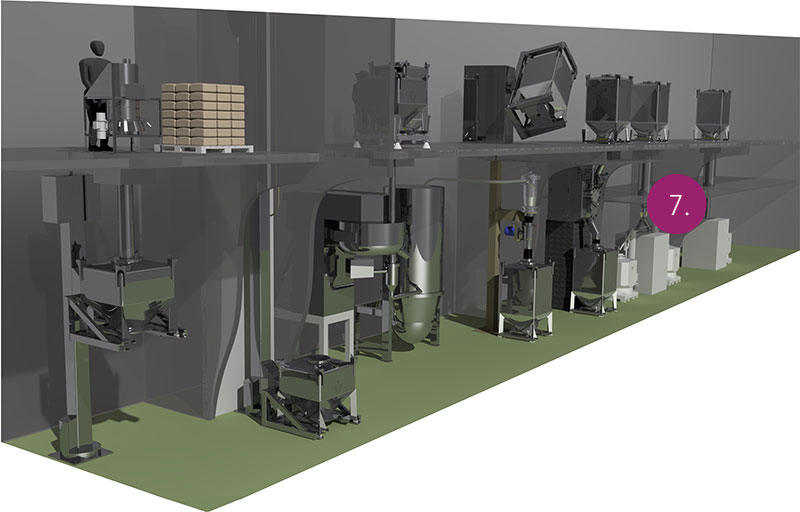

- Compatible with single-sided or double-sided tablet presses

- Suitable for use with double-layer tablet presses

- Large batch transfers possible

- High processing efficiency

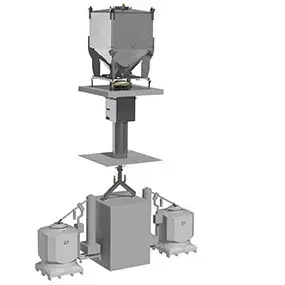

- Single-floor or through-floor feeding capability

Related Pages

Click on the links below to access the other processing steps: