Tablet Inspection

A full tablet or capsule batch can be gently transferred with minimal operator intervention, saving significant operator time compared to traditional drums.

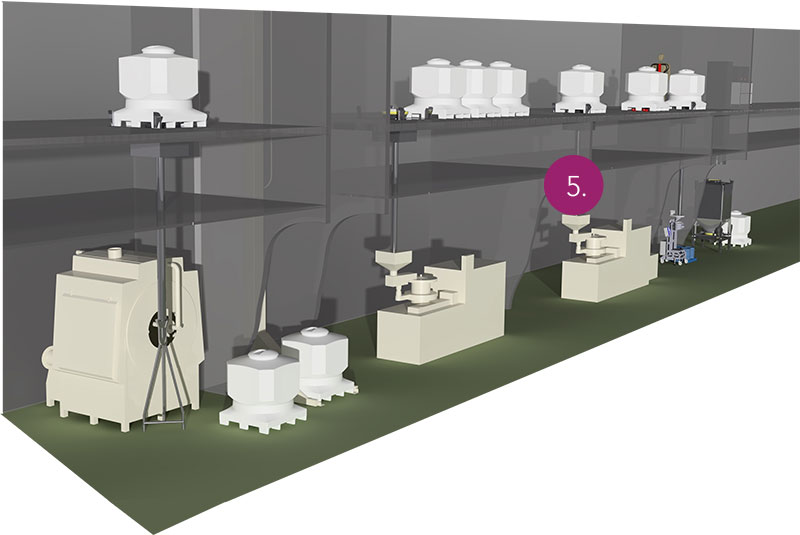

Instead of manual feeding the Tablet Inspection equipment, a full coater batch can be automatically fed from a Tablet IBC. By not splitting the batches it reduces the number of connections to make/break and container movements.

This reduces operator involvement and means it can be conducted as a closed process in line with GMP.

More Ergonomic

Tablet IBCs enable automation of the transfers, reduces the number of movements between process steps and labour for operators.

Features at a glance

- Large batch transfers possible

- High processing efficiency

- Gentle tablet handling design

- Single-floor or through-floor feeding capability

Related Pages

Click on the links below to access the other processing steps: