03 October 2023

Matcon is pleased to present the new Pilot Scale Blender, a new innovation in..

Matcon in-bin blending powder mixer systems ensure that your materials are mixed effectively and your operation becomes more efficient with reduced cleaning downtime.

Industrial powder mixing using IBC Tumble Blending delivers the following benefits:

Do you need further information about a Matcon Product? Complete the form and our team will contact you.

Container mixing has long been established as an efficient and effective way to blend bulk materials such as powders and granules.

Rapid batch changeovers are easily achieved with the Matcon IBC Tumble Blender. There is no need to clean down this industrial blender as the ingredients are fully contained within the IBC, making lengthy product changeovers a thing of the past.

Whilst one IBC is being blended, the next can be filled which means there is no need to stop mixing, enabling parallel processing. Fast, efficient powder handling.

Achieve high overall equipment effectiveness (OEE) rates as IBCs are formulated and discharged separately from the blending process. Learn more about our blending systems with the brochure.

With a Matcon IBC Industrial Blender, you can mix any recipe any time, making your manufacturing production more efficient and flexible.

As the IBC is the blending vessel, loading, unloading and cleaning time is greatly reduced. The IBC filling and emptying processes take place independent of the blender and there is no downtime for cleaning or risk of cross-contamination.

If you need to blend a variety of batches then an IBC blender will enable you to efficiently manufacture a wide range of recipes and batch sizes.

The system is always blending providing high OEE – filling, emptying, and cleaning is done offline.

In-bin blending for instant recipe changeovers without risk of contamination.

Better batch capability means that you can manufacture a wider range of batch sizes.

Intensifier package expands blending capability, including liquid addition.

Modular solution: factory assembled, proven design, low risk.

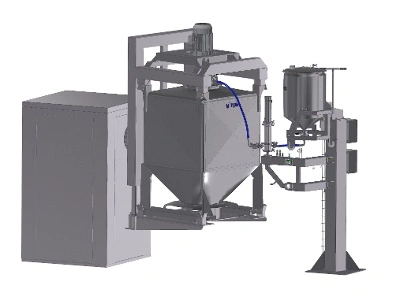

The Pilot Scale Blender for compact low volume powder blending.

Ideal for testing proof of concept in the development of recipe formulations on the pathway to scale up, or for high value, low volume powder batches in small scale production runs.

The Pilot Scale Blender offers the convenience of mixing low-volume batches at any given moment. This blender is specifically designed for mixing smaller quantities of powder, making it perfect for testing the proof of concept in recipe development or for producing high-value, low-volume powder batches.

The blender setup includes essential features such as a safety guard, Pilot Scale IBCs, and an optional High Shear Intensifier. These components ensure a safe, smooth, and efficient discharge process.

With the addition of the Intensifier, the blender's mixing capability is enhanced by incorporating high shear into the blend. This feature also extends the range of recipe development possibilities. Furthermore, there is an option to include a MicroNIR Spectrometer, which provides valuable information on blend homogeneity.

The Pilot Scale IBCs are available in 100L and 200L volumes, equipped with castors for easy movement, and fitted with a Matcon Manual Cone Valve in the outlet. This valve ensures the mass-flow discharge of powders, effectively protecting the quality of the blended powders.

Watch the video below to see the pilot blender in action.

The Matcon Intensifier introduces high shear mixing to the IBC blending process and expands blending capabilities.

More cohesive powders can be blended and single-stage bakery mixing is possible. The Intensifier is the ideal solution where the addition of liquid is required for a recipe.

By adding a high shear cutter to the Matcon Blender, recipes can be mixed and materials dispersed which will not blend by flow alone, enabling liquid fats to be incorporated and more cohesive powders to be processed and agglomerated lumps removed.

Using an IBC Blender will eliminate inefficient cleaning practices associated with traditional static mixers.

Expand the range of IBC powder blending.

High shear cutter blades are easily added.

Air-purged Intensifier option for high sugar content recipes.

Cleaning 'offline' significantly reduces mixer downtime.

Easy to load and unload with handling trolley.

Mix liquid fats efficiently in single-stage blending.

Efficiently disperse micro-ingredients ensuring a quality final product.

High shear without heat build-up – particles are blended without degradation to achieve a quality final product.

Efficient cleaning off-line with cleaning trolley.

A revolutionary development to expand the range of IBC powder blending to increase efficiency and reduce risks.

Automatically inject liquids directly into a powder mix, enclosed within an Intermediate Bulk Container during its blender rotation cycle, without manual intervention or the need to open the blending vessel.

As consumer demand continually changes, manufacturers must have flexible and efficient production processes to stay ahead of their competition.

Until now, if a powder blend required liquid addition, using a Fixed Powder Blender or Mixer was necessary, which can be difficult and time-consuming to clean between recipe changeovers.

Invented and developed by Matcon, our innovative (Patent Pending) Liquid Addition System expands the range of the IBC tumble blender and is well-suited to industries that need the flexibility to mix a wide range of powder recipes in a contained and efficient manner.

This flexible and hygienic system enables batch-based blending to reduce manual handling and improve containment levels. This ensures that manufacturers can further enhance their IBC Blending function.

Key advantages of liquid addition:

| Feature | Low Volume System | High Volume System |

| Addition volume | 1 - 10l | 5 - 150l |

| Vessel (liquid bottle) options | 5l / 10l | 150l |

| Liquid shot volume range (per revolution) | 100 - 500ml | 200 - 800ml |

| Column height (inc vessel) | 2m | 3.1m |

| Liquid viscosity capability | Up to ~56mPa.s | Up to ~56mPa.s |

Use Near-Infrared (NIR) spectroscopy to identify when a mix is homogenous.

Near-infrared (NIR) spectroscopy is a fast and flexible technique to analyse and verify the content of any powder recipe mix.

Applied in a wide range of research and industrial process applications, this technology has proved itself to be a cost-effective tool when measuring recipe mixes. This ensures that manufacturers optimise their processes and reduce costs.

Ideally suited for use on the Matcon IBC Tumble Blender

Wireless operation - battery powered

Analyse new recipes and optimise existing recipes

Non-destructive technique

Mounted on IBC lid for ease of operation

Suitable for use on multiple types of equipment

Efficient and flexible manufacturing equipment for high quality production

Matcon IBCs are efficient, dust-tight powder containers, manufactured to the highest standards for all industry applications.

Formulate powder recipes directly to IBCs with accurate, automated filling and add into your batch processing flow as required.

Mix powder recipes of all sizes any time using an IBC Tumble Blender. Improve loading times, cleaning and remove bottlenecks.

Over the years we have seen a wide range of different powder types and production issues that our Cone Valve technology has been able to overcome. This gives us the confidence to believe we can handle any challenge you wish to put to us.

© Copyright IDEX 2024

Privacy Policy*Required Fields