03 October 2023

Matcon is pleased to present the new Pilot Scale Blender, a new innovation in..

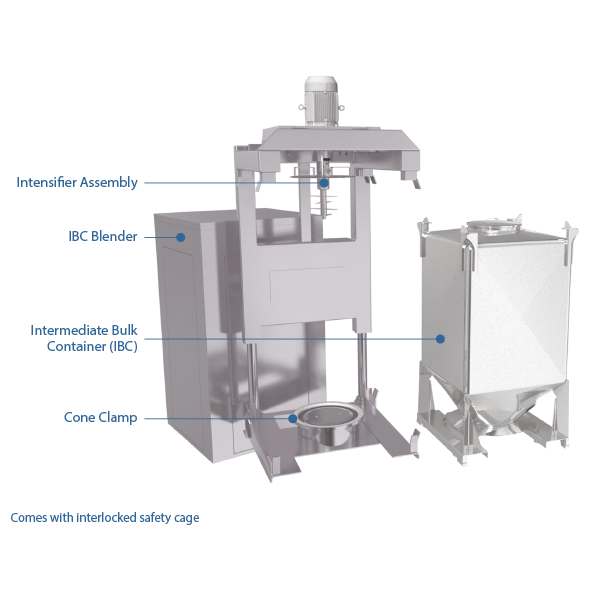

Batch changeovers are instantaneous with SMED. No need to clean between recipe batches as the IBC is the blending vessel – simply remove & clean offline. High mixer OEE rates are achievable, which maximises production capacity.

Tumble blending on an asymmetric axis achieves blend uniformity and is a well-established efficient alternative to traditional fixed mixers.

Blend times can be further optimized using NIR as it monitors homogeneity in real time. Blend times can be reduced & over-mixing prevented without the need for invasive sampling.

Batch volume flexibility is achievable with IBCs ranging from 500L to 3,300L and the ability to fill IBCs at 20% of capacity.

Mix any recipe at any time

Achieve high OEE rates (overall equipment effectiveness)

Fast recipe changeovers

No risk of cross-contamination

Formulation, packing & cleaning are all independent from blending

Handle volume variability with different sized IBCs on one blender plinth