19 January 2021

A major pharmaceutical company, with multiple facilities in its global..

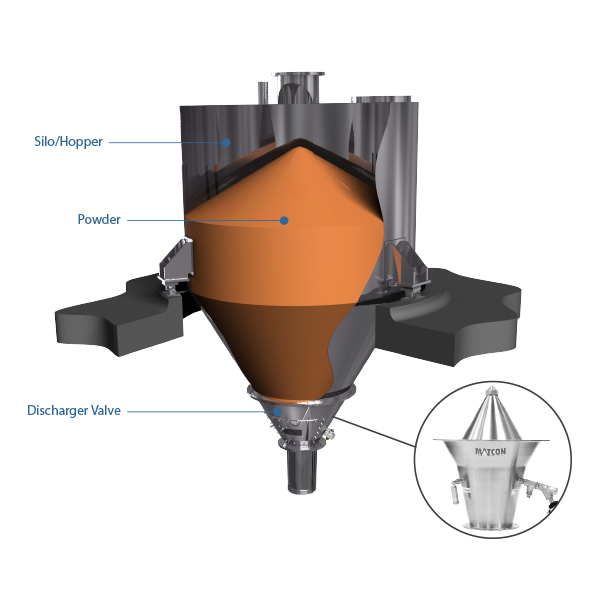

Designed to fit silos and hoppers & equip them with Cone Valve Technology to deliver controlled discharge of bulk powders. The Discharger Valve acts as both a flow aid, metering device and shut-off valve in one.

The valves are available in a range of sizes from just 500mm to 2.5 metres in diameter. Our experts can help you ensure you have the correct sized valve to suit your application and powder flow characteristics.

Actuator driven, using compressed air, to provide the lift force of the internal cone which stimulates the powder flow.

Retrofittable to existing silos and hoppers

Controlled dosing from adjustable lift heights

Robust & reliable, with easy maintenance

As a discharge device: the powerful lifting & vibration overcomes bridging & ratholing of powders

As a valve: the cone valve's vertical movement means it can be shut off at any time to stop product flow

As a feeding device: the high level of control means it can be used to meter material to a level sensor or specified weight

Blend Segregation

Blend Segregation