INDUSTRIES

Manufacturing Equipment for Animal Nutrition Products

Ensuring each bowlful of animal feed, pet food, and nutritional supplements is correctly balanced is vital and doing so efficiently is the route to success.

INCREASING PRODUCTION CAPACITY

for animal nutrition products

The versatile Matcon powder and materials handling system can overcome your dry processing challenges when producing animal nutrition, livestock feeds and nutritional supplements.

Matcon's powder processing and mixing equipment enable the decoupling of your manufacturing processing steps. We help companies to achieve flexible and efficient manufacturing system practices using the principles and practices of lean manufacturing to transfer dry powder materials.

YOUR CHALLENGES

Mixing challenges for animal nutrition manufacturers

Ensuring dispersion of micro and minor ingredients is essential in providing a quality product every time.

Cross-contamination of ingredients, a constant risk with traditional fixed mixer production systems.

De-mixing of blends on transfer to packing results resulting in scrapped batches & increased manufacturing costs.

HOW WE CAN HELP

Improving animal nutrition manufacturers productivity

The requirement to manufacture such a varied portfolio of products has forced producers to adopt highly flexible manufacturing operations to meet with demand. Matcon IBC Technology will allow you to adapt to market changes, adhere to regulations, modify the way you operate and create new ways to enhance your production.

Thede-coupled nature of the Matcon Intermediate Bulk Container (IBC) system makes it easy to produce a variety of products in a short timeframe.

In-bin powder mixing reduces downtimes for recipe changeovers and removes risk of cross-contamination as the batch ingredients are fully contained within the IBC, so with no need to stop the production line entirely to clean down the Blender, lengthy product changeovers can be a thing of the past.

The unique Cone Valve technology contained in each Intermediate Bulk Container (IBC) protects any blends

against segregation and provides guaranteed discharge, helping even the stickiest of products to flow effectively and under control.

OUR EXPERIENCE

Working with animal nutrition manufacturers

In the animal nutrition sector, Matcon have experience of nutrition, medicinal and agricultural applications, handling a range of ingredients including grains, proteins, vitamin and mineral nutrient premixes, and extruded products.

IBC tumble blending is proven to increase the range and quality of pre-mixes that our customers manufacturing dry pet foods can offer, whilst retaining their high-quality assurance standards. As batch ingredients are fully contained within the IBC, there is no need to clean down the Blender, significantly reducing downtimes for product changeovers and any risk of cross-contamination is also removed.

A well designed, agile, Lean system means our customers easily switch recipes in response to demand.

Animal Nutrition manufacturers that make the move to IBC-based production, have the ability to run smaller, tailored, flexible batch sizes in parallel, reducing loading, cleaning and discharge times. And the great thing with an agile system like this, is that new bins of varying sizes can be added at any time, so scaling to meet market demands doesn’t mean costly factory extensions or refits.

OUR APPROACH

Working with animal nutrition manufacturers

The need for flexibility in any manufacturing process is one of the biggest challenges in industry. Manufacturers must evolve and adapt their production methods so that they can easily and quickly respond to customer orders.

The Matcon IBC System achieves this flexibility by following the principles of Lean Manufacturing and through parallel processing, where the manufacturing steps are decoupled. Formulation, blending, packing, and cleaning take place simultaneously, maximizing the Overall Equipment Effectiveness (OEE) of the feed manufacturing process.

Advancements in IBC tumble blending technology allow manufacturers to use Intermediate Bulk Containers (IBCs) to quickly change over recipes, add liquids to blends, and curtail the risk of cross-contamination with improved containment.

Our unique Cone Valve technology inside each IBC provides automatic and controlled discharge of virtually any powder type and has continually proven to overcome powder handling issues such as bridging and rat-holing, whilst protecting the blend against segregation.

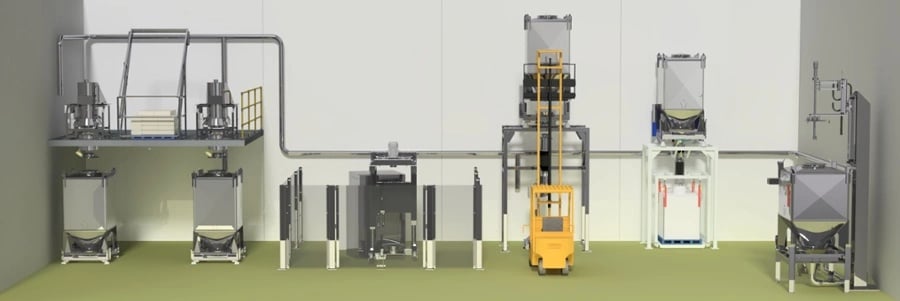

SYSTEM MODULES

Powder Handling Systems for Animal Nutrition

This simple system is all you need to get started the right way. By decoupling the processing steps we enable companies to achieve a flexible manufacturing system.

The Matcon system is based on using Intermediate Bulk Containers (IBCs) to transport powders between manufacturing steps and as a blending vessel. Because everything is contained within the IBC, there is no clean-down of the blender between recipe changes, which gives you the ultimate flexibility of operation.

LEARN MORE

Resources and Information

Equipment guidance and useful information for manufacturers of animal nutrition products.

- Meeting customer demand in the Animal Nutrition Industry

- Technology for more flexible manufacturing in the Animal Nutrition Industry

- How to Increase Productivity in 6 Steps

- Why Animal Nutrition Manufacturers Choose Cone Valve Technology

- How to deliver tailored animal nutrition orders quickly and efficiently

- Powder Ratholing Problems Solved