For some of our customers we are seeing a trend towards scaling up and using very large IBCs up to 3500L. These big bins are useful to reduce the amount of handling needed to move materials around the production line and reduce the amount of QA testing required. We are seeing a trend towards scale-up within the Generic Pharmaceutical market. If this is your requirement too, or you are looking into scaling up your Pharmaceutical manufacturing process, here are some words of advice.

We have already published a selection of blogs on designing the right factory to suit your needs and a whitepaper on designing taking a look at the pro’s and con’s of single-floor and multi-floor designs. The next step is to choose the right supplier of your materials handling system.

Our advice would be to tread carefully as not all IBCs are equal in functionality & manageability. What initially looks like a cheaper option may not give you the performance you need. It is worthwhile spending some time understanding the benefits and limitations of the different types of IBC valve outlet.

Which IBC Size/s Suit Your Pharmaceutical Manufacturing Process?

One thing to consider is the range of IBC sizes that can be manufactured. If you are producing lots of different products, you may have different batch sizes, so IBCs that are all compatible no matter the size is vital. You don’t want to have to split batches unnecessarily.

Does a Butterfly Valve Suit a Large IBC?

A butterfly valve IBC may not be able to cope with this volume, particularly if the material being handled is cohesive. It is likely that product will be prone to bridging, so the material immediately above the outlet will evacuate, leaving material caught up higher up the bin. As we mentioned in a previous blog this material is extremely difficult to remove from the IBC safely and without damaging the product.

What to Consider When Scaling Up

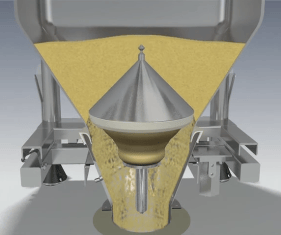

If you are scaling up to a larger sized IBC it is worth considering how Matcon can help. We have over 35 years of experience in interfacing our IBC systems with pharmaceutical equipment. Our unique Cone Valve technology within each of our IBCs helps cohesive products to flow by the lifting action of the cone and the integral cone vibration which takes place at the top of the lifting cycle, breaking down any bridging. Even at 3500L IBCs product can be stimulated to flow without the need for more aggressive vibration methods.

If you are scaling up to a larger sized IBC it is worth considering how Matcon can help. We have over 35 years of experience in interfacing our IBC systems with pharmaceutical equipment. Our unique Cone Valve technology within each of our IBCs helps cohesive products to flow by the lifting action of the cone and the integral cone vibration which takes place at the top of the lifting cycle, breaking down any bridging. Even at 3500L IBCs product can be stimulated to flow without the need for more aggressive vibration methods.

If the product is very free-flowing and prone to flushing, again the Matcon Cone Valve technology has an advantage in offering a variable lift-height of the cone which means that product flow can be specifically controlled to avoid any over-feeding of downstream pharmaceutical equipment. We discussed this in a previous blog "How to Get Control of Free-Flowing Powders in Your Pharmaceutical Equipment."

Can the Large IBC be Used for Partial Discharge of Powder?

In addition, due to the cone valve within each IBC, flow can be shut off at any time. The cone closes under gravity in the direction of powder flow. This is ideal if only partial discharge of an IBC is necessary.

A System Designed for Automated Discharge

If you are using large IBCs it is most likely that your factory is a multi-floor design. The Matcon system is designed for automated discharge processes, which can be integrated with your existing equipment to ensure call-off of product at the correct rate. We have supplied large IBCs in single floor facilities where they are separated from personnel and equipment.

Large Scale IBCs Don’t Suit Every Pharmaceutical Facility

Not all sites will need large scale IBCs, so it is worth matching your IBC volume to your batch sizes. This is something we do every day at Matcon and we are happy to advise you. We aren’t just suppliers of IBCs, we take pride in our consultative approach. We design a materials handling system that delivers you the right throughput to match your customer demands. If you are tempted by the alternatives, we would advise you to study them in great detail before committing one way or the other.

We have put together a handy checklist of questions to help you when choosing the right equipment for your facility. Use the information and ask suppliers of IBC systems to ensure that you get the best one for your needs.

Posted by

Matt Baumber