Consumer demand and industry regulation are often cited as key influencers in a growing market, but it is often engineering manufacturers that underpin industry change by enabling producers to better compete and innovate. Over recent years, new technology is speeding up production processes throughout the food industry in Europe. Manufacturing automation and new process methodologies have allowed early adopters to be more flexible while still maintaining quality and safety standards.

We interviewed Matcon's Regional Sales Manager Neil Brown to discuss how the European Food Industry has changed in the last three years and the influence he feels engineering manufacturers have had on that change. This article summarizes Neil’s views on key changes that have taken place in the food industry and why producers should look to engineering manufacturers to help them remain competitive.

Holding an MBA, and with a background in engineering with the Royal Navy, Neil knows first-hand about the impact that equipment can have on an organisation and how important it is to stay up to date.

“I joined IDEX with a goal of helping manufacturers who were losing market share through no fault of their own—other than a lack of updated machinery and knowledge—and help to enable them to compete on a global scale.”

Technology ages regardless of what industry you’re in, but with the pace at which the food industry has changed recently, food manufacturers acknowledge that their legacy equipment directly affects their competitiveness. Food manufacturers that plan for business improvements through capital investment will always be one step ahead of their competition. When you add this to the process inefficiencies of aging equipment, the gap between competitors widens very quickly and food producers who were once market leaders can suddenly find themselves behind.

The biggest industry change that has affected food producers is the increased customer demand for more product variety

Neil described a confectioner that he had worked with as a good example of one of the issues affecting the European food industry. To satisfy market demand, the confectioner needed to produce higher levels of bespoke product, rather than daily mass production of the same product, as they had done for years.

Each time they were required to switch production to a different variety, a complete system stop and clean down was required leading to extremely high levels of lost production time. The more they tried to satisfy market demand, the less they were able to meet the demand while still being profitable.

In addition to not meeting demand, they identified that:

- Their legacy equipment was designed primarily for producing large amounts of the same product and they lost significant production time during batch changeovers due to stoppages and cleaning

- Inadequate cleaning led to higher risk of contamination and potential cross contamination of allergens

- Cleaning validation, product traceability and accurate labeling were becoming increasingly difficult with the limitations of legacy equipment

- They faced increased competition from suppliers with newer equipment and processes designed specifically for multi-variant manufacturing

Neil had numerous examples of leading food producers attempting to maintain market share using legacy equipment but all experiencing the same issues.

“Huge silos are great for making the same product day in day out, but the consumers were driving the market towards variety rather than quantity," explained Neil. "What began just a decade ago as a growing trend has now gone mainstream making it very difficult for traditional food producers to compete. Across Europe the demand for recipe and product diversity is only going to increase.”

Consumers are more aware of allergens in ingredients

Neil added that although variety was a key market driver, the increase in allergen awareness has also affected the industry greatly. The potential for brand damage is huge if a product is miss produced or miss labelled, or worse, fails to alert consumers correctly of an allergen within a food product.

Matcon Technology helps food producers to gain market share

As Neil realized that more and more food producers were experiencing the same production limitations, he looked to align himself with an engineering technology that could help the food producers compete.

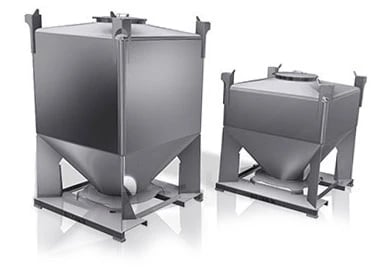

Neil joined Matcon in July 2019 and brought his strong engineering skills together with his knowledge of the changing food production marketplace. Neil feels strongly that Matcon's patented Cone Valve IBC system is a perfect solution for food manufacturers to be able to compete in today's marketplace.

About Matcon's Regional Sales Manager Neil Brown

Education: University of Liverpool

Degree: Master of Business Administration (MBA)

Field of Study: Business Administration and Management, General

The Manchester Metropolitan University

Degree: Bachelor of Science (BSc)

Field of Study: Food Technology and Processing

Neil has previous experience in the ready meals, bakery, confectionery and meat industries as follows:

Zeppelin Systems, business development manager for food

BCH Ltd, technical sales manager

Holmes Farm, multisite technical manager for food

Greenhalgh’s Craft Bakery Ltd, quality assurance technologist

Royal Navy Artificer

Contact Neil today if you would like to explore your manufacturing challenges or feel that your business has fallen behind its competitors and would like to explore options to improve productivity. nbrown@idexcorp.com or call +44 7935 901670

How Matcon and Bakels worked together to increase product variety

Download the Case Study to see how Matcon Technology helped British Bakels Ltd gain a competitive advantage.

“We can now offer an enhanced product range, better flexibility of pack sizes, along with significantly enhanced quality assurance and customer service.”

British Bakels Ltd

Read how British Bakels Ltd became more flexible when they introduced in-bin blending saving them cleaning time and improved their throughput rates by reducing mixing times. The Matcon IBC system removed the risk of cross-contamination enabling multiple product varieties to be safely and efficiently produced.

Posted by

Matt Baumber