Would you like the capacity to double the tonnes of products manufactured per shift but don’t have the budget or space to expand your facility? There’s a simple solution and it’s one that we have implemented for food and nutrition manufacturers that want to increase production. With most of our customers their one main regret they have is allowing their fear of change to get the better of them and not moving on this sooner. The outcome, savings and increased revenue completely out-weigh the initial investment and upheaval involved. The longer you put off the inevitable, the more revenue your business is losing so move now.

Contained Mobile System Compared to a Fixed System

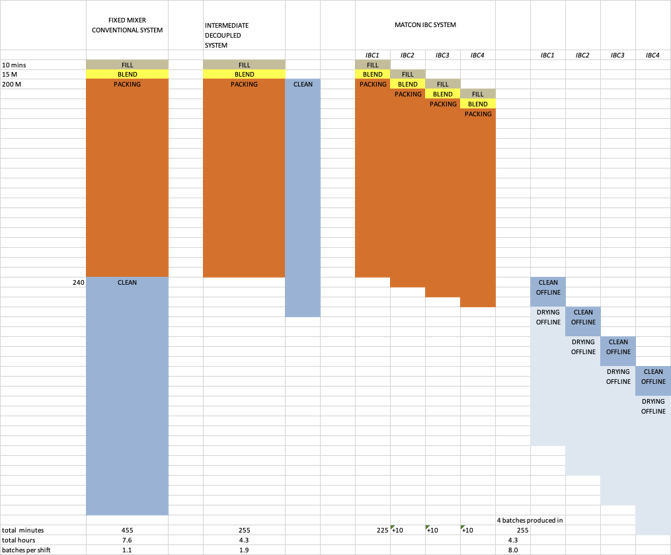

If your factory operators could do two things at once without compromising on quality, they’d do it, right? This is possible with a mobile system that uses IBCs (Intermediate Bulk Containers). For example, while your blender is mixing, pre-filling, then cleaning and packing can be actioned simultaneously. Many manufacturers forget to include the full operating times of production when adding up the minutes it takes to produce each batch. You need to ask how long it takes to fill your mixer, to optimally blend your ingredients, the time taken to empty your mixer (packing) and then how long your mixer is off-line while in the process of thorough cleaning and validation before it’s back in operation. In this diagram see the huge increase in production that could be realized by using a flexible system:

To find out exactly how long your actual processes take in your own facility, use our calculator to see how much more product you could be producing if using a flexible, IBC (Intermediate Bulk Container) system:

What Do You Have to Lose?

Making a change to increase your production, reduce your losses, improve your product quality and hygiene levels sounds great but as a manufacturer we understand that you need to know that this would work for your specific operations, recipe ingredients and product before investing.

This is why we follow a phased approach before you make that change. You can stop at any point in this staging if you feel that improvements can’t possibly be made. Likewise, we occasionally stop this process ourselves for manufacturers producing products that just don’t fit our system e.g. high bulk, low end materials that don’t need mixed, quality, hygienic, consistent batch production.

Our Phased Approach looks a bit like this:

- Information Gleaning

You tell us about your product, operations and facility layout and any issues you’d like to solve e.g. you’d like to increase your production levels but feel that your operators and processes can’t work any faster or more efficiently than currently.

- Site Visit

If we feel efficiencies could be made, we’ll visit your site to walk your factory floor, take an audit to understand your business, chat to you and the operators that have hands on experience in the day to day running of your facility.

- Technical Proof

If you require proof that additional equipment or replacement equipment does work/fully mixes your specific materials, this stage can take place at one of our global testing facilities using only your recipe and the specified equipment. You can analyze your tested final product for the data you need.

- Historic Data

In our 35+ years, we have collated vast amounts of data on numerous products produced around the world, so this archive can be tapped into to see any similarities with your ingredients and how challenges have previously been over-come and efficiencies made.

- Objectives

Set your goals of what you’d like to achieve and by what time e.g. double tonnes of product by next year / increase ROI by X etc.

- Road Map

We create a road map of your current state compared to how your future state could look.

- Implementation

If you wish to implement any additions / replacements to your current operations, a gradual introduction can be installed or a total switch, if preferred.

Every customer is different, from the size, type, location of their facility to the current system they have in place. The product recipe is always different down to the origins of the source materials and logistics to particle size and texture of your powders. Therefore, a thorough investigation is advised before any changes to processing or equipment take place.

Don’t take our word for it

Read this customer’s story on how implementing an agile production system has generated an instant return on investment such as:

- Cleaning times were reduced from 480 hours to just 70-man hours

- 55% reduction in manufacturing time

- Reduced inventory, releasing $228,000 back into the business

- Improved OEE rates

- Labor costs reduced by 25%

- Reduced packaging tonnage by 45%

Download the Case Study by clicking below.

Posted by

Matt Baumber