Adhering to food safety standards is vital in the food manufacturing industry.

Regulatory authorities such as the FDA & the FSMA are setting ever higher standards, which can feel more restrictive. Meanwhile, consumers demand more transparency in operations, requesting that companies can trace the source of ingredients, and ensure products are produced sustainably and with the highest quality standards. How can you match the market needs as well as regulatory requirements but remain competitive?

Bearing in mind the FDA Food Safety Modernisation Act (FSMA) is aiming to shift the focus from responding to contamination issues to preventing them, are you going to be compliant?

This doesn’t just apply to those manufacturing in the USA, but all overseas facilities that export to the USA too.

Coupled production systems where the fixed mixer is directly linked up to the packing line can be cumbersome in this scenario. How can you be sure that every last bit of the line is contaminant free? If you are to be sure, how long will it take to make a full clean-down and validation?

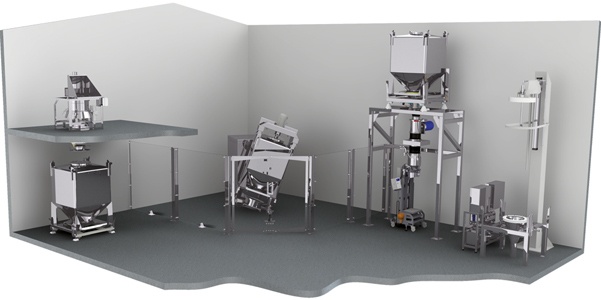

Here at Matcon we have experience of designing IBC system solutions for both the Pharmaceutical and Food industry sectors. With high hygiene standards built in and the ability to track recipe batches, product can be safely and transparently produced.

A Matcon IBC solution provides peace of mind through supplying a system based on individual containers holding the production batch. The whole system remains fully closed at all times thereby reducing the risk from cross-contamination and protecting the workforce too.

Our systems are designed to meet strict FDA regulations and have been designed with GMP in mind.

Further benefits include reduced cleaning times even though we still match the required high hygiene standards.

Although we can deliver to these high standards, production flexibility is not compromised. You can still produce to order and accommodate high recipe variation. Speak to our team to learn more.