If your manufacturing facility does not meet the latest regulations, you will not be able to sell to other countries. The message is clear, and for most manufacturers this is not new news. What has changed in the South East Asia region is that regional Government agencies such as the Ministry of Health (MOH), Badan Pengawas Obat (BPOM) and the Makanan, an Indonesian Agency for Drug and Food Control is tightening its controls to match those adhered to in other regions. They are now aligning to guidelines set out by the UK Food Standards Agency (FSA), the Allergen Bureau in Australia and NZ Food Standards Code (FSANZ) to name just a few.

Take action today to minimise the risks in your food manufacturing facility and align production with the new allergen food information regulations introduced.

Reasons Why These Regulations Are Getting Tighter and Key Drivers for Manufacturers

Allergen regulations have been introduced to protect the consumer, standardisation across these regulations and greater enforcement is now commonplace. With these measure in place, they give manufacturers the ability

- To sell and export to many countries

- To keep ahead of their competition

- To maintain their reputation

- To minimise public health consequences

- To increase the quality and consistency standards of their products

- To improve their facilities working environment for operators

No manufacturer wants to experience a recalled product. The financial costs and reputational costs are too great to consider. However, according to the Allergen Bureau in Australia and NZ Food Standards (FSANZ) - Between 1 January 2010 and 31 December 2019, FSANZ coordinated 707 recalls. The average number of recalls per year for the last 10 years has risen to 71 (previously 67)

Getting Serious - Worldwide Stats of Public Food Allergies and Food Intolerances

Millions of people suffer allergic reactions to food each year. Although many food allergies can produce quite mild symptoms, some can cause serious reactions, and could even be life-threatening.There is no cure for food allergies therefore management of allergen containing foods during production is vital to avert consequences. Here are a few of the stats on worldwide food allergies and intolerances:

World-wide 1 in 10 adults and 1 in 13 children suffer from a food allergy – say the Food Allergy Research and Education (FARE).

Celiac disease affects approximately 1 in 100 individuals – say the Celiac Disease Foundation.

Food allergy cases have risen by as much as 50 percent in the past decade with a 700 percent rise in hospitalisations due to anaphylaxis. Globally, more than 250 million people suffer from a food allergy with more than 17 million people suffering from food allergies in Europe alone

More than 150 million Europeans suffer from chronic allergic diseases and the current prediction is that by 2025 half of the entire EU population will be affected.(EAACI, 2016)

Allergy is the most common chronic disease in Europe. Up to 20% of patients with allergies struggle daily with the fear of a possible asthma attack, anaphylactic shock, or even death from an allergic reaction. (EAACI, 2016)

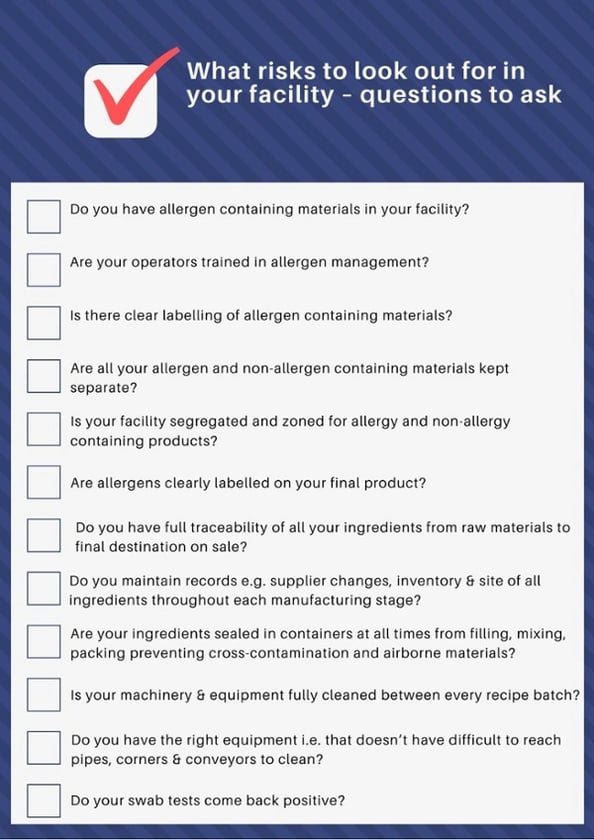

What Risks to Look out for in your facility – Questions to Ask

A good place to start when carrying out your risk assessment on allergens in your food manufacturing facility is to look at the number of allergens onsite at any one time and to map out your processes and traceability of ingredients from suppliers of raw materials to final product. This will highlight where you prioritise reducing the risks.

Your people and equipment need to be in line with your allergen management plan from the start or your allergen risks will remain a problem to you.

The Solution

Reducing the risk of cross-contamination is paramount to any food manufacturer and by decoupling your processing stages, you are able to achieve a flexible production line.

Traditionally, static, fixed mixers and all the equipment and conveyors that are coupled to it are difficult to dismantle and clean between each recipe batch. This also takes operators a significant amount of time to clean and validate. Most importantly, while the clean down process is taking place, production has to stop with this traditional coupled manufacturing method.

The Matcon solution uses Intermediate Bulk Containers (IBCs) to transfer powders between each production stage and also becomes the mixer container. As all the materials are contained and sealed within the IBCs, there is no cleaning of the mixer between recipes and the risk of cross-contamination during production is also significantly lowered. Additionally, the Intermediate Bulk Container (IBC) system can be more easily tracked to improve batch traceability.

Ask for Help

Some food manufacturers are unfamiliar with these regulations as they are relatively new in some countries and they just need a little extra help to get them on track. We are here to advise manufacturers like you to minimise the allergen risks in your facility, aligning it with the latest regulations in your country. Often small production changes can have a huge effect on mitigating allergen risk. So much so that you will wonder why you haven’t explored them sooner. Contact us and we’ll help you explore what options are available.

Posted by

Matt Baumber