Bridging, arching, blocking, and powder segregation are the traditional powder handling challenges when handling powder materials.

in your manufacturing facility, you might regularly ask yourself.

- Is the product quite sticky and poor flowing?

- Why are we having trouble getting it out of your containers?

- How can we stop our powder blend from segregating during discharge?

- What methods do we need to use to free this powder?

Over the years we have seen many manufacturing facilities where the powders have got stuck in the outlet of the container or hopper. In order to free the material, we have seen operators use mallets to thump the outside of the bin or rods to try to unblock the obstruction. Hammering the side of the equipment both distorts it and only leads to problems further down the track.

Not exactly good manufacturing practice either.

So, what has happened in the bin to cause this? We often see the common causes:

- powder ratholing

- arching and bridging.

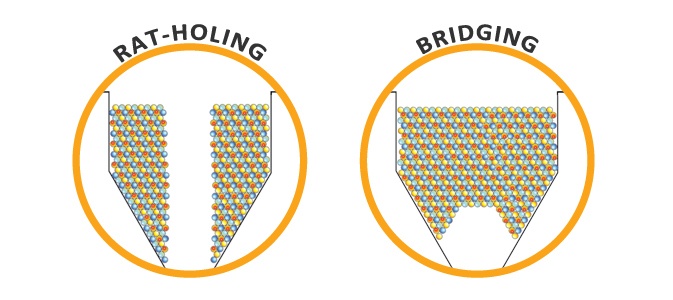

What is Rat-holing?

Rat-holing happens when flow only takes place directly above the outlet of the container. Product at the sides gets held up and can cake or agglomerate. Once the central core is discharged, flow stops and the rest of the material remains stuck to the sides. This is when the mallets are deployed, to help create vibration and free the material. The sloping hopper/bin walls are not steep enough or low enough in friction for material to move, so instead the particles cling to the sides and themselves. This core flow means that particles can have a tendency to segregate, which means the blend becomes demixed. Yield is also poor as the product sticks to the sides of the container.

What is Powder Bridging?

Powder Bridging is when an arch-shaped block of powder forms above the outlet. It is caused when particles interlock and become cohesive. Initially product flows, but this quickly stops once the free material is discharged. At this point the container is usually opened from above and rodded. This of course can create a dusty environment and can sometimes be a very hazardous operation.

How can you Improve the Flowability of Powders?

There are several options available to correct this problem. The first is to use the geometry and the material of the hopper to induce movement. Material flow is determined by a combination of the angle at the bottom of the hopper and the friction caused by the internal surface, so for instance, a shallower angle could be used if the surface has low friction, or a rougher surface would need a steeper angle.

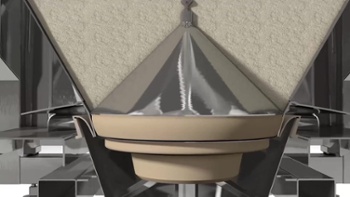

Alternatively, we would promote the use of our unique Cone Valve IBC system. As the cone rises during the discharge process, the vertical lifting action breaks any bridges in the powder material. At the top of the lift, there is also a small vibrating action, which further loosens any sticky product.

The annular gap (ring-shaped gap) that is formed in the outlet of the IBC as the cone lifts creates mass flow of the material. This means that powder flows across the whole cross-sectional area of the container, with all the particles moving downward at the same rate, with the product that entered the IBC first, being the first to be discharged, what is called ‘FIFO’ (first in, first out). This prevents material from being left behind on the walls of the IBC.

By the nature of how the powder is discharged from a Matcon IBC, the particles don’t move against each other, so each dose out of the container should be the correct mix.

Segregation or de-mixing is avoided, giving consistency across the finished product and a quality product in the final consumer pack.

To discover why Cone Valve technology overcomes the traditional powder problems please download our free whitepaper below:

Topics:

Powder Handling Problems