Within our powder handling systems for manufacturers of sports nutrition powders lies our unique technology that will help to future-proof your production line.

It is helping to change the way Sports Nutrition powder-based products are being made.

It’s a radically different production method to the fixed inline process and it works.

Using Intermediate Bulk Containers (IBCs) to move materials through the production steps and also to process powders creates a fully flexible manufacturing system. Because the IBC becomes the blending vessel there is no product contact with the blender, resulting in no need to clean between recipe changes. Batch changeover can be instantaneous. In addition, because the whole system is unconnected, the batching and emptying of the container all takes place off-line, thereby eliminating all blender idle time. Which is in stark contrast to a fixed mixer which sits idle for a large proportion of the shift whilst it is being filled, emptied or cleaned.

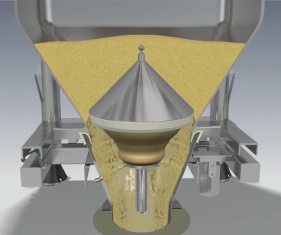

What is the unique technology for handling sports powders?

The Cone Valve is a unique discharge device that’s included in all our IBCs and has revolutionised powder handling. Cone Valve IBCs succeed in overcoming a range of powder handling issues from bridging to segregation and core-flow.

They offer automatic and controlled discharge of virtually all powder types via an integral cone vibration system. Consistently powder will flow smoothly and cohesively, giving you complete control of the discharge process and a quality product that is right the first time every time.

Matcon’s Cone Valve technology will bring numerous benefits to your powder production line and your bottom line:

- Blend homogeneity is maintained throughout the transfer process – vital for consistency and quality across your product range and ultimately repeat orders.

- Dust-free atmosphere – powder is contained within a system that remains closed at all times via an outer lip seal on the discharge station. This removes dust hazards and reduces the chances of cross-contamination.

- Accurate dosing – the Cone Valve opens and closes vertically so can be shut off to stop product flow completely at any point. This enables precisely measured amounts to be used for batch dosing or for part used IBCs to be removed from the discharge station.

We understand the sports nutrition manufacturing industry, the most common challenges faced and help companies like yours to overcome these challenges. You can speak to our technical engineers who can advise you on implementing the most efficient, flexible manufacturing equipment from initial setup to your future business growth.

In the meantime take a look at our whitepaper which explores the different types of manufacturing systems being used in this marketplace and the Return On Investment of each one.