In the battery manufacturing industry, we are witnessing consistent innovation and progress. Matcon, with its extensive experience in collaborating with battery material manufacturers, established battery cell manufacturers, emerging start-ups, and R&D entities for gigafactory developments, is now stepping forward to tackle the inherent complexities of battery powder handling challenges with practical problem-solving tools.

Navigating the Scale-Up Journey: Matcon's Blueprint for Powder Handling Excellence

At every stage, there's a conversation about scaling up sagely, about ensuring your powder handling growth from lab to pilot to full-scale production doesn’t become a bottleneck.

As a trusted partner in this journey, Matcon has worked with a diverse portfolio of global clients, including battery material manufacturers, electrode producers, and other stakeholders in the supply chain. While each of these entities has distinct operational hurdles, they all share a common objective—to amplify efficiency and safety in their processes.

.webp?width=556&height=822&name=Battery_blog_discharge_of_powder_IBC%20(1).webp)

At the heart of Matcon's innovative solutions are the Cone Valve Intermediate Bulk Containers (IBCs), utilised for both processing and handling powders. These IBCs enable exceptional reliability in powder feeding into Loss-In-Weight feeders, a critical aspect of continuous slurry production in battery manufacturing. Moreover, they ensure secure material transfer during crucial stages in Cathode Active Material (CAM) or Anode Active Material (AAM) production facilities. By addressing the challenges of powder handling with Cone Valve IBCs, Matcon not only enhances the operational efficiency and safety of these processes but also contributes significantly to the scalability and reliability of battery manufacturing operations.

When it comes to material handling, challenges may not surface during early lab-based chemistry development or even when scaling up to several hundred kilograms. The real test begins when dealing with hundreds or thousands of kilograms of product in a single container – whether that is in a big bag or IBC. At this scale, it can be problematic to get the powders out of the container without adversely affecting the powder composition. That’s where the Matcon Cone Valve IBCs come into play. Our technology ensures smooth and controlled discharge of powders, mitigating the risk of segregation and degradation of the material. This feature not only preserves the quality of sensitive battery materials but also maximises the efficiency and reliability of the manufacturing process.

In conclusion, scaling up is an indispensable ingredient for any process's success. However, it is not as simple as magnifying your lab procedures. The shift demands strategic planning, precise execution, and, most importantly, an expert partner like Matcon.

Join us on this journey of scalable excellence! We're not just keen observers; we're active listeners—partner with us to unveil the most effective solutions for your needs.

Engagement with Pioneering Battery Start-Ups and The R&D Sector

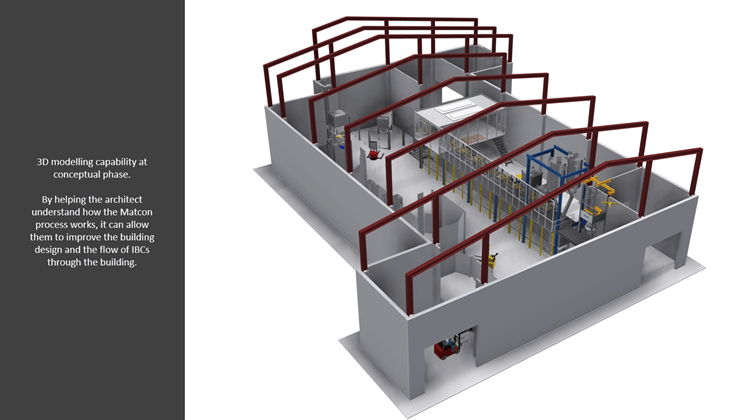

With visionaries crafting the future with each battery prototype—there's resonance in our aim to provide not only solutions that meet today's needs but ones that can evolve organically with tomorrow’s demands. With over 40 years of experience in powder handling across various industries, Matcon guarantees first-rate process consultancy and expertise. We specialise in upholding powder quality, improving process efficiency, and optimising yield, irrespective of the powder's characteristics.

The strive for innovation and agility aligns with Matcon's solutions that promise quality and scaled production.

For established or battery material manufacturers

Interestingly, our narrative is not woven in isolation. Organisations involved in the Battery sector wrestle with the dualities of innovation vs ROI, striving to boost production efficiencies while vigilantly overseeing their facilities to ensure they are outfitted with top-of-the-line manufacturing equipment capable of sustaining their operations. This often entails contending with integration and compatibility hurdles that could impact the entire production process.

The answer lies in a supplier with a proven track record—Matcon’s Cone Valve IBC based powder handling systems are purposefully designed to address efficiency gains and versatility that powerhouses in the field can rely upon. For well-established manufacturers, maximising productivity is crucial when considering new process equipment investments. Making informed decisions is paramount in this assessment. Matcon's reputation is built on its ability to assess potential, facilitate integration, and strategically form partnerships to deliver optimal engineering solutions for its clients.

Fitting into the Canvas of Innovation

At Matcon, we know the power of realistic ambitions. We transcend typical vendor status, becoming partners who acknowledge the grit it takes to convert concepts to real-world applications. And yes, while we certainly don't hold centrality in the battery manufacturing process, the role of powder handling is no less critical. We're the silent assurance to process engineers, R&D, chemical engineers, and innovators that as your endeavours mature and capacity demands soar, the powder handling infrastructure won't betray you.

For companies in the intricate realm of battery manufacturing, contemplating future issues amidst current challenges may appear indulgent. Yet, by contacting the Matcon team, we could offer a glimpse of a future where powder handling is expertly managed.

The Matcon Proposition:

- Real-talk about real problems: A candid discourse on scaling up and the inevitable powder-handling challenges you'll face.

- Confidence through experience: Seeing is believing. We offer complimentary powder tests that demonstrate how our solutions can work for you.

- Innovation that integrates: The importance of creating a system that grows with your production, never against it.

Expertise at Your Elbow: Have the opportunity to engage with powder handling experts and engineers who design systems to align with your objectives.

To all at the cusp of greatness in battery innovation, chat with us. Whether you're drawing upon the wellspring of academia's latest or juggling the variables in the manufacturing realm, our message is consistent—Matcon is here to pave the way for seamless scalability and powder handling precision in your growth narrative.

Posted by

Matt BaumberTopics:

Battery