We just wrapped up Appex 2024. Among the notable participants, our stand carved a distinctive presence as we talked about our recent blending innovations.

Networking at the event went beyond the mere exchange of business cards. Our conversations were fruitful, fostering deep discussions that connected the dots between the technological potential and real-world applications across diverse industry sectors.

Here's an inside look at the products that stole the spotlight:

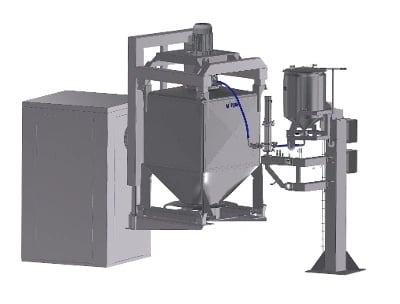

Pilot Scale Blender: Your Gateway to Versatility

Stepping into uncharted territories? Our Pilot Scale Blender is not merely new; it is a revolution. Tailored for operations handling high-value, low-volume items, it's the perfect companion for manufacturers exploring diverse product ranges. Fostering the spirit of experimentation, this blending marvel promises flawless mixing, cost-efficiency, and ease of use.

Advantages of the Pilot Scale Blender

- Precise Mixing of High-Value Products

- Expedited Experimentation for New Recipe Formulations

- Scalability for Niche Market Demands

- Cost-Efficiency without Compromising on Quality

High Shear Intensifier: Power Tool for Full-Scale Blending

Presenting the High Shear Intensifier, set to redefine IBC blending. This powerful addition dramatically improves the blending process, introducing the dynamics of high-shear mixing. The result? A more cohesive blend with the added possibility of single-stage mixing. This tool is more than just a game changer; it represents a complete paradigm shift for battery manufacturers delving into powder fibrillation.

Why High Shear Matters

- Expanded Blending Capabilities

- Cohesive Powders Become Manageable

- Efficiency of Single-Stage Mixing

- Enhanced Powder Homogeneity

Liquid Addition: Precision, No Compromise

Precision is non-negotiable in manufacturing. At Matcon, we understand this, which is why we introduce Liquid Addition, an automatic system enabling the injection of liquids directly into the powder mix within the IBC. It's a paradigm shift, eliminating the need for manual intervention and capitalising on operational efficiency.

The Liquid Addition Advantage

- Timely Liquid Incorporation

- Reduced Risk of Cross-Contamination

- Enhanced Process Efficiency

- Improved Product Quality

Air Washing: A Zero-Compromise Solution

Hygiene and contamination control are critical, especially when handling sensitive products. Our Dry IBC Washing System exemplifies our commitment to maintaining the highest standards of cleanliness without the need to remove the Cone Valve.

Why Our Dry Washing is Superior

- Complete Inside Wash and Dry off the IBC

- Eliminates the Need to Remove the Cone Valve

Real Success Stories: Putting Matcon to the Test

While innovations often promise the sky, success is truly measured in the ground reality. At Matcon, our solutions aren't just theoretical. They're practical and tested, delivering exceptional value to our esteemed clientele.

Rain Nutrience Case Study

Rain Nutrience doubled its production rates and future-proofed its facility, all without adding resources or increasing factory space. Our IBC technology helped them process and handle more significant varieties of powder, streamlining their operations for sustainable growth.

Bakels Bakery Case Study

Bakels Bakery's agile system now copes effortlessly with small batch runs, various recipes, and safe allergen handling. Matcon's blending solutions facilitated a seamless shift towards enhanced flexibility without sacrificing efficiency or safety.

Testimonial from True Protein

"The Matcon IBC Blending Systems allow us to blend much larger batches than our previous system, providing significantly increased efficiency," said Ben Kierath, Managing Director at

True Protein.

Take the Next Step: Harness our Expertise with a Free Consultation

As part of our ongoing commitment to your success, we're offering a complimentary consultation. Engage with us on a deeper level, scrutinise our equipment, and envision your business powered by innovation.

Remember, our commitment to your success extends beyond the initial sale. We offer aftersales services such as Spares, Upgrades, and Support, ensuring your operations continue to function seamlessly.

GET IN TOUCH

Arrange for a call back and consultation

As part of our ongoing commitment to your success, we offer a complimentary consultation for those keen to explore how our technology can enhance your manufacturing and blending processes. To arrange a call, please complete the form, providing your preferred contact details.

Posted by

Matt BaumberTopics:

Blending