Achema is the ‘World forum for the chemical engineering and process industry’

This year's event hosted over 3,800 exhibitors, discussing the focal topics of flexible production, biotech for chemistry and chemical logistics.

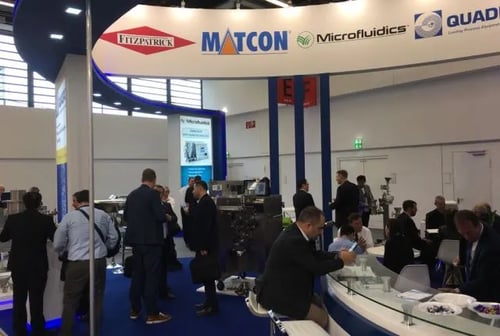

The Matcon team was in attendance alongside our IDEX Material Processing Technologies (MPT) colleagues from Quadro, Fitzpatrick and Microfluidics.

Following an active week in Frankfurt, discussing the latest key industry topics and showcasing Matcon’s equipment we gathered the thoughts of our Pharmaceutical Business Line Director Richard Lockwood.

Having attended Achema before in 2015, what are your overall views of Achema 2018?

The size of Achema never ceases to amaze, the sheer scale was very noticeable. There is certainly a good range of exhibitors and delegates from all over the world. I expect you would need at least two days to walk the exhibition sufficiently.

The exhibition at Achema covered all areas of biotech, flexible production and logistics; it was great to see so many solutions for the range of challenges facing the market. The international presence of the exhibitors was probably wider than that of the visitors, the spread of stand shape & size was also wide, some huge stands occupying several 100m2 to those of just a few 10s of m2 alongside one another.

From our perspective, we had the opportunity to talk to a multi-national mix of visitors on the stand. We welcomed a high percentage of visitors from India & China, whose roles ranged from Engineer to Director.

What were the products and services you discussed the most at the event?

As ever the Cone Valve display attracted a lot of attention. It proves a great way to draw people to the stand. The exhibit is always popular as it allows us to demonstrate our ability to handle challenging materials as well as delivering consistent feed to compression machines, roller compactors and remove bottlenecks around the process.

It is clear from talking to our clients that the lean philosophies used for so many years in our non-Pharma business are now of relevance to the pharmaceutical market, gone are the days when processes can take time to change over, bottlenecks across the process are being uncovered.

The visitors from India were very interested in the local support we are now able to offer from both a sales and service point of view.

Everything often comes back to the Cone Valve the benefits it delivers, but everyone has a different level of interest. The CEO often wants to know how he can use IBCs to maximise revenue, whereas the Operator is keen to hear how his life will be made better in a dust free, efficient factory.

What were the common challenges being faced by delegates?

Lack of flow was the most common problem people wanted to address, whether it was experiencing issues on site with existing IBCs or those looking to move toward an IBC system but were expecting challenges in this respect.

As the needs of the (Pharma) market develops in Europe how can Matcon support manufacturers?

The main area of focus right now for Matcon in Pharma is India & Bangladesh, the key here is to support our Clients every step of the way, helping them to develop the best concept for their facility through to working with them to ensure the technology is applied in the most appropriate way. Our local team of Support Engineers are crucial in ensuring this is delivered effectively and we can continue to deliver a superior customer service.

How will you follow up after this event, what are the next steps?

Personally my follow up will be to support our RSMs with the relevant supporting information and experience that allows them to best solve the Clients challenges, travelling where necessary to hold follow up discussion in person.

To learn more about Matcon’s services or to speak to Richard directly please get in touch via the contact us page.

Posted by

Matt Baumber