Welcome to the Battery Developer Hub

Your dedicated resource of engineering insights for optimising powder management in battery production.

WEBCAST SERIES

Battery Powder Management Solutions Explored

In this video series, we explore ways to address powder-handling challenges typically seen in the battery industry and showcase innovative equipment designed for the industry.

Led by our in-house battery expert, Richard Lockwood, each session draws on the vast experience of Matcon's skilled engineers. These insights are designed to enhance production processes and boost battery performance through effective powder management strategies.

The Matcon System and the Advantages of IBCs for Powder Handling

See how the Matcon system addresses common powder-handling problems in battery manufacturing and creates effective production solutions.

Processing Solvent-Free Electrode Powders with High Shear Blending

Discover how our High-Shear blending technology transforms an IBC from a transport vessel into a versatile processing solution and promotes powder fibrillization.

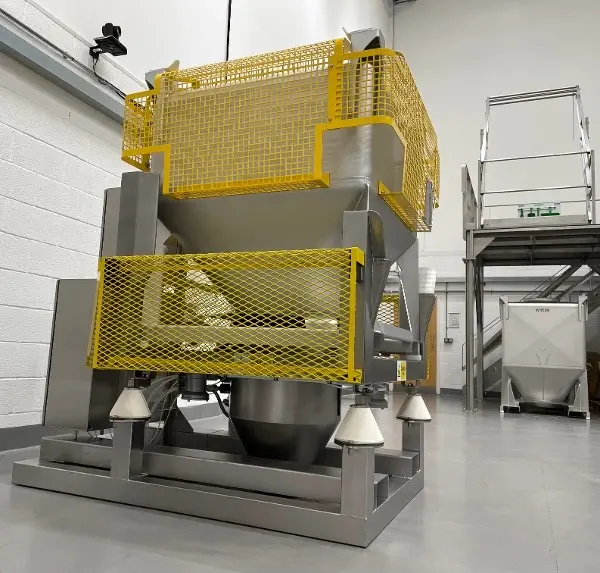

The Pilot Scale Blender

and Its Benefits for Proof of Concept

Discover how this innovative equipment can optimize your processes before scaling up. Fitted with High-Shear and the Cone Valve technology, you can test all aspects of the Matcon offering.

Efficient Solutions for Hot Powder Management

Engineered to accommodate up to 200°C, this advanced system allows manufactures to collect and process hot powders, eliminating the need for extensive cooling mechanisms.

Solutions for Competitive Battery Powder Materials

As the battery industry advances, our technology evolves to meet demands for higher energy density. See how we empower manufacturers to enhance battery chemistry and maintain a competitive edge.

Powder Handling Systems - The Matcon Cone Valve

Our proprietary technology ensures precise discharge of almost any type of powder, improving efficiency and ensuring powder homogeneity. Ready to gain control of your powders?

Preventing Moisture Ingress

Excessive moisture during battery production can cause corrosion and reduce performance. It can also accelerate material degradation and shorten the lifespan of the final product. To maintain the integrity of battery powders, gas inerting techniques are used to replace ambient air with gases such as Nitrogen or Argon during the IBC filling stage.

Handle Hot Powders

We have developed an IBC and discharge system that safely and effectively discharges handles powders at temperatures up to 200 °C (392 °F).

This ability can significantly reduce the size of cooling equipment and can lead to substantial CAPEX and OPEX savings.

Powder Fibrillization

By streamlining the traditional "powder–slurry–film" process into a more efficient "powder–film", this method eliminates the need for energy-intensive drying techniques. Our IBC tumble blender with Intensifier applies high-shear forces to encourage fibril formation, enabling the powdered material to develop into a cohesive structure.

Innovation for Every Challenge

Innovation drives our commitment to overcoming the unique challenges inherent in battery production environments. If you are facing a specific challenge or have yet to find a solution, we invite you to reach out to us. Together we will engineer solutions that enhance your operational efficiency and success.

Empowering Manufacturing

Flexible Solutions in Battery Powder Formulations

When standard solutions fall short, our advanced engineering expertise is crucial for achieving manufacturing objectives.

Here are a few examples of our innovative problem-solving in action.

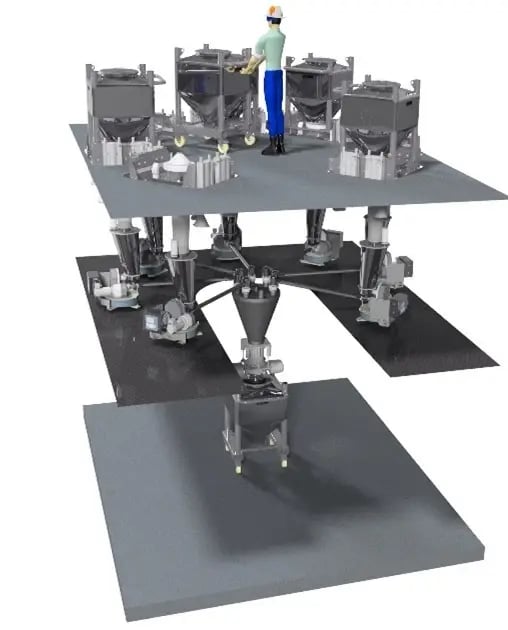

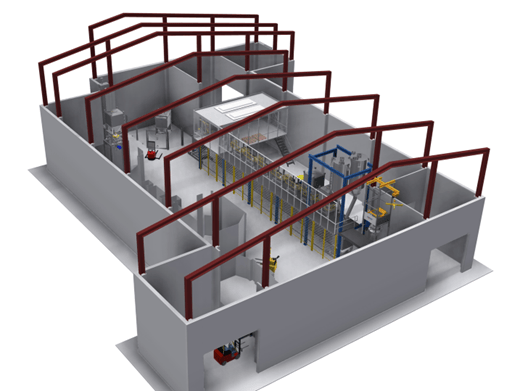

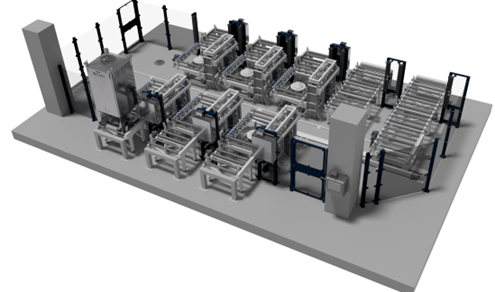

Our equipment is impressive on its own, but when combined, it creates powerful systems that provide manufacturers with the flexibility and automation needed to scale and stay competitive.

Each Matcon system is custom-tailored to fit specific manufacturing needs and plant layouts, offering clients a perfect blend of bespoke solutions with off-the-shelf modular components. This approach ensures ease of maintenance and adaptability to future manufacturing demands without becoming a long-term maintenance burden.

In this process flow the system efficiently manages powders from sources like mixers and sack tipping, transferring them to the furnaces positioned under discharge stations. This automation allows operators to fill IBCs as necessary, while the system autonomously handles container movement and processing. This capability ensures a continuous feed to the furnace, whether using a single ingredient or a powder blend, with minimal need for manual intervention.

For this R&D facility, there were significant space constraints. It was not possible to give access to forklifts, thereby necessitating manual handling of the IBCs for the formulation, blending and discharge processes.

We developed a system that allows operators to efficiently move containers using rolling castors. Actuators lift the discharge stations to connect with the IBCs. After discharge, the IBCs are easily rolled into & out of each manufacturing process step, ensuring manual handling is safe and efficient.

In this project, we collaborated closely with the architect to maximise floor space efficiency.

The building was divided into two key areas: one dedicated to raw ingredient storage and dosing, where big bags feed IBCs, and the other designed for formulation, blending, and packing.

The client opted for a glass wall between the areas to enhance visibility and use it as a site reference. Thanks to the dust-free Matcon system, the glass wall requires minimal cleaning.

In this instance, our primary goal was maximising throughput while minimising operator handling. We implemented an RFID system to enhance operational efficiency. This setup utilises a series of conveyors to manage IBCs. As one IBC on the discharge station is depleted, it is automatically removed, and the next full IBC is transitioned into place.

The process operates within a multi-floor structure. IBCs are loaded onto a goods elevator from the ground floor and gradually transported to the top floor through the process. Once there, the containers enter the automated conveyor system, eliminating the need for manual intervention.

For this application, the client needed a powder grading system to maximise yield and ensure efficient material utilisation.

We implemented a recirculating approach for grading. This method stacks the equipment into a vertical line.

Powders are processed through a Roller Compactor and mill which precisely resizes the powder particles, significantly reducing powder waste that would otherwise be discarded due to out-of-spec particle size distribution.

The Matcon advanced powder feed control is crucial for this system to be effective as it allows fresh powder to be integrated into the system while also enabling recirculated powder to be incorporated.

GLOBAL REACH, LOCAL EXPERTISE

Testing Units for On and Off-Site Trials

We understand the importance of flexibility and accuracy when testing your powders. That's why we offer different routes to testing. We can supply units for you to use at your facility or come to one of our Testing Centres.

Our road testing units include Intermediate Bulk Containers (IBCs), discharge stations and pilot-scale blender. The IBC units are available in pilot and full-scale, allowing testing of anode, cathode, and electrolyte powders on-site.

Additionally, we have specialised testing facilities in key locations.

Test Centres

Our facilities are designed to simulate actual working conditions using your specific blend recipes. This ensures that your test results represent real-world operations, giving you peace of mind and reliable data.

GET IN TOUCH

Speak with an application expert

Whether you are aiming for commercialization, expanding operations, or improving your current production techniques, enhancing the efficiency of the battery handling process is essential.

Reach out to our team of application specialists to take advantage of our expertise and experience.

Resources

Related Resources

Equipment guidance and useful information for Battery Manufacturing.