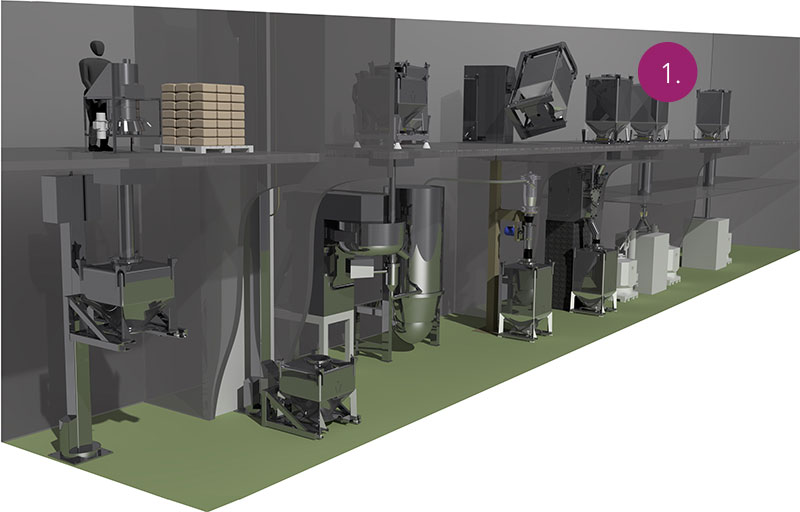

IBCs for Pharmaceutical OSD Powder Handling

Pharmaceutical OSD powders are efficiently handled using an IBC system solution. Sizing the IBCs to match the throughput objectives will maximise system efficiency and minimise operator workload.

We offer a wide range of IBC sizes from 50 litres to 3500 litres to match system requirements. Smaller scale IBCs are ideal for processing small order sizes, whilst bigger batches or combining lots are possible with the large scale IBCs.

Cone Valve Control

The unique Cone Valve technology within each IBC prevents the traditional powder handling issues of bridging, rat-holing and blend segregation. Compared to butterfly valve containers it provides superior discharge control, no matter whether you are handling free-flowing or cohesive materials, even in the biggest sized IBCs.

Features at a glance

- Range of sizes to suit manufacturing volumes

- Easy handling & maneuverability

- Stackable to save floor space

- Storage capability with air tightness over the long term

- Discharge control preventing segregation, rat-holing & bridging

Related Pages

Click on the links below to access the other processing steps: