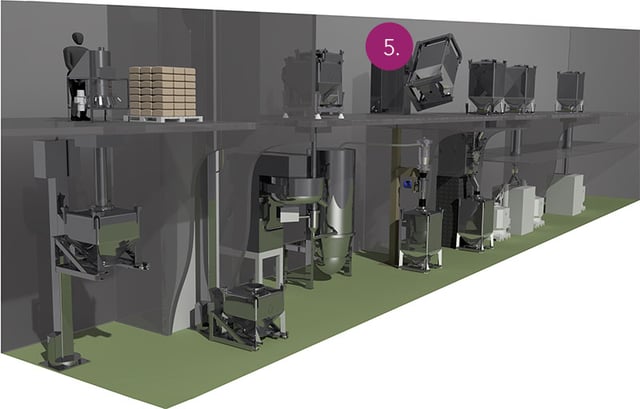

The Matcon Blender eliminates the time-consuming and costly cleaning associated with traditional stationary mixers such as V-blenders, double cone or other fixed shell blenders as the IBC itself is the blending vessel.

This enables fast changeover between different batches or products. Blended product is taken directly to the next process stage removing the risk of segregation on transfer.

The IBC Blender has a small footprint therefore requires less space and means that clean-room demands are reduced, for a more cost-effective building design.

The Matcon Blender is able to accommodate IBCs of varying sizes. A single blender can blend batches from 20kg to 1400kg. With blenders up to 3500L we can cater for many different needs.

One single blender is able to replace multiple fixed mixers for a more efficient blending process. Vital in a multi product facility.

Over the years we have seen a wide range of different powder types and production issues that our Cone Valve technology has been able to overcome. This gives us the confidence to believe we can handle any challenge you wish to put to us.

© Copyright IDEX 2024

Read Our Privacy Statement

Contact Us

Standard T&Cs of Sale

Careers